AFD310

The AFD310 is part of PushCorp's Active Compliance series. This end effector can apply up to 60 lbf [267 N] in any orientation, automatically. Consequently, this tooling is essential for automating robotic, material-removal applications where parts have complex or curved geometries.

The STC1503-BT30, SM1503, STC0605-BT30, and SM0605 are servo spindles optimized to mount to the AFD310. Together, they can automate a wide variety of robotic processes:

If the application will have impact loading, interrupted cuts, or require a heavier spindle, our AFD620 is the second largest in the series. It features a more robust set of linear bearings and can apply 115 lbf [511 N].

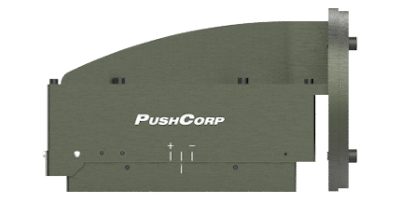

The AFD310 Series is available in two configurations: AFD310-1 Vertical and the AFD310-2 Horizontal. The units are functionally identical but differ in the orientation in which they attach to the robot. The AFD310-1 applies force perpendicular to the robot's face plate, whereas the AFD310-2 is parallel. These configurations allow you to optimize a robot’s reach and dexterity for your particular application.

The FCUFLEX controller is used to set the applied force and monitor I/O. This equipment can be controlled using a PLC, robot controller, or PC.