Routing, cutting, and milling are high-speed material removal processes that demand precision, rigidity, and operator safety.

Routing trims, shapes, and contours materials like fiberglass, composites, plastics, and wood using high-speed rotary tools.

Cutting removes or separates material with end mills, burrs, or saw-style cutters.

Milling machines precise profiles, pockets, and features in metals, plastics, and composite parts.

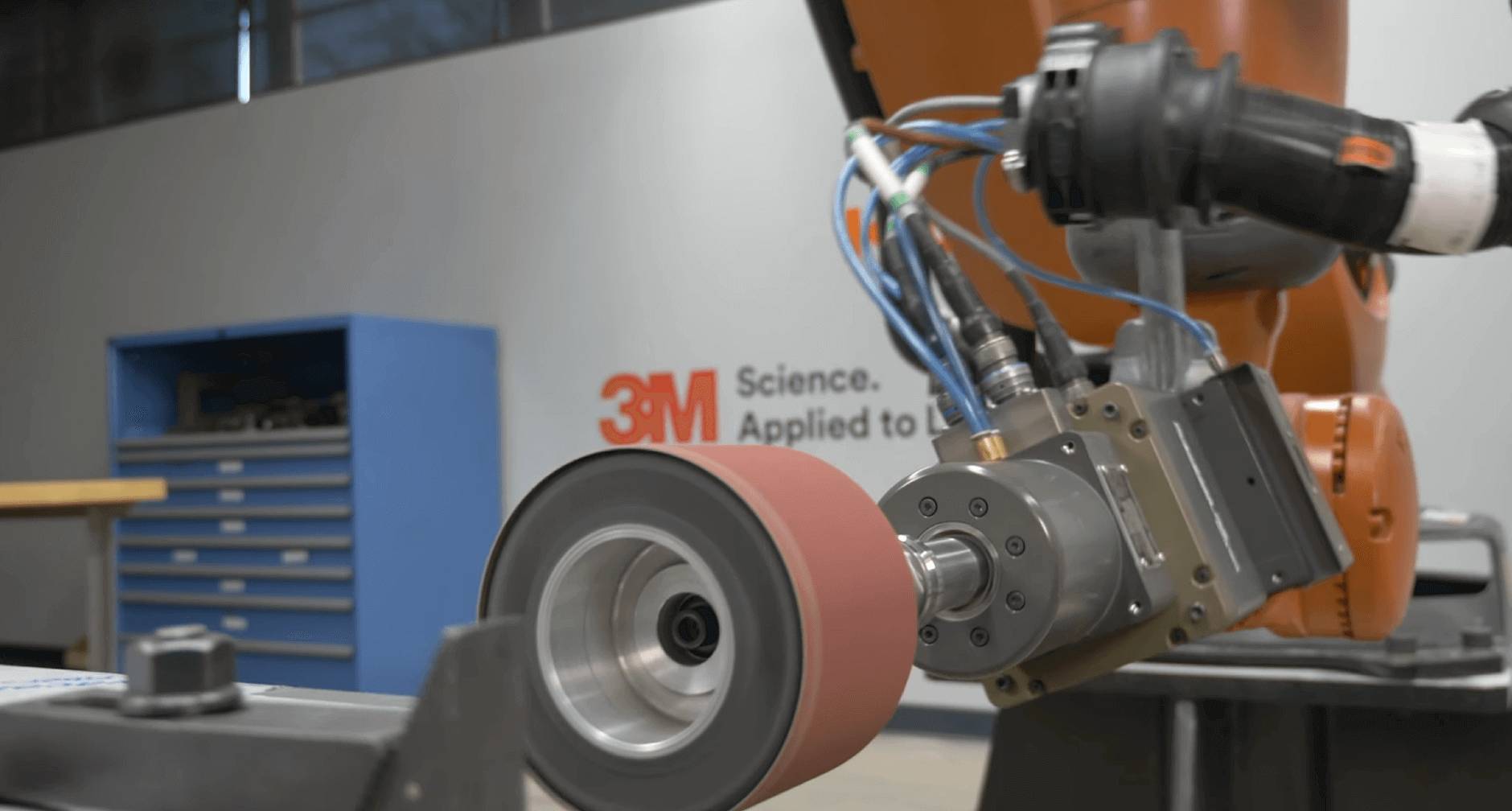

These processes are tough, dusty, and risky to perform manually. Automating them with robotic routing, cutting, and milling improves safety, reduces variation, and delivers clean, consistent edges and profiles across every part.