Servo Spindle Motors Overview

Industry Standard BT Toolholder

Air pressure actuated, industry standard, BT-style toolholders are our most popular tool-changing option. Our spindles accept either the BT30 or the larger BT40 toolholder, depending on the motor size. BT-style toolholders are readily available from a variety of tooling suppliers in various lengths and configurations. They provide exceptional holding torque and tool retention, and they can accommodate a wide range of tool diameters. This exceptional performance and flexibility make them the go-to choice for most any application.

Manual Collet

Our Manual Collet option uses a standard ER-style collet and nut. This simple, low-cost solution is ideal for grinding, brush finishing or other applications where media changes are required but not frequent enough to justify full, robotic, quick-change technology. ER collets are readily available from many suppliers in a variety of size options to accommodate most any tool.

BT Toolholder Tool Change

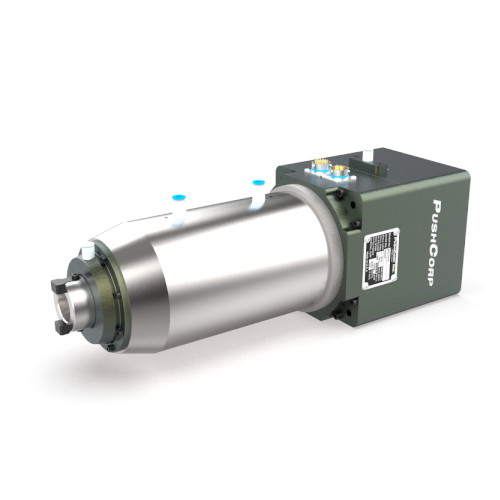

STC1503-BT30

STC1503-BT30 High-Speed, Robotic Servo Spindle The PushCorp STC1503-BT30 high-speed servo spindle is an ideal solution for robotic, material-removal applications such as:…

Learn More

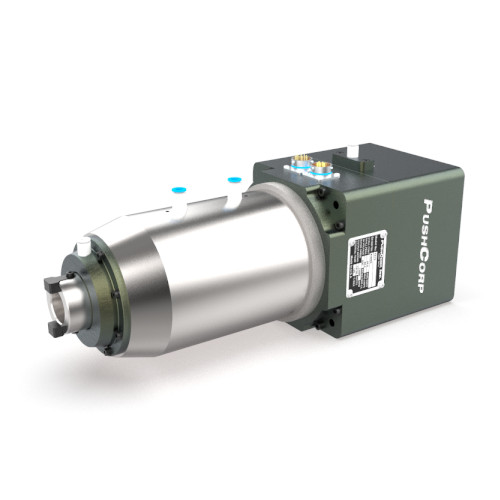

STC0605-BT30

STC0605-BT30 High-Torque, Robotic Servo Spindle The PushCorp STC0605-BT30 high-torque servo spindle is an ideal solution for robotic, material-removal applications such as: Robotic…

Learn More

STC0612-BT40

STC0612-BT40 High-Torque, Robotic Servo Spindle The PushCorp STC0612-BT40 high-torque servo spindle is an ideal solution for robotic, material-removal applications such as: Robotic…

Learn More

STC1015

STC1015 High-Torque, Robotic Servo Spindle Motor The PushCorp STC1015 high-torque servo motor spindle is an ideal solution for automated, robotic, material-removal…

Learn More

STC1515

STC1515 High-Speed, Robotic Servo Spindle The PushCorp STC1515 high-speed servo spindle is an ideal solution for robotic, material-removal applications such as: Robotic…

Learn MoreManual Tool Change

SM1202

SM1202 Series High-Speed, Robotic Servo Spindle The PushCorp SM1202 high-speed servo spindle is an ideal solution for robotic, material-removal applications such…

Learn More

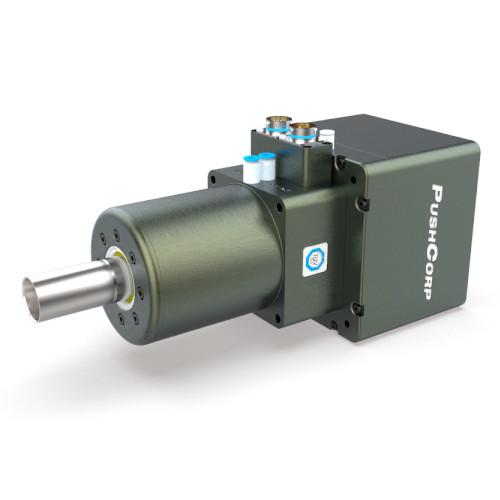

SM1503

SM1503 High-Speed, Robotic Servo Spindle The PushCorp SM1503 high-speed servo spindle is an ideal solution for robotic, material-removal applications such as: Robotic…

Learn More

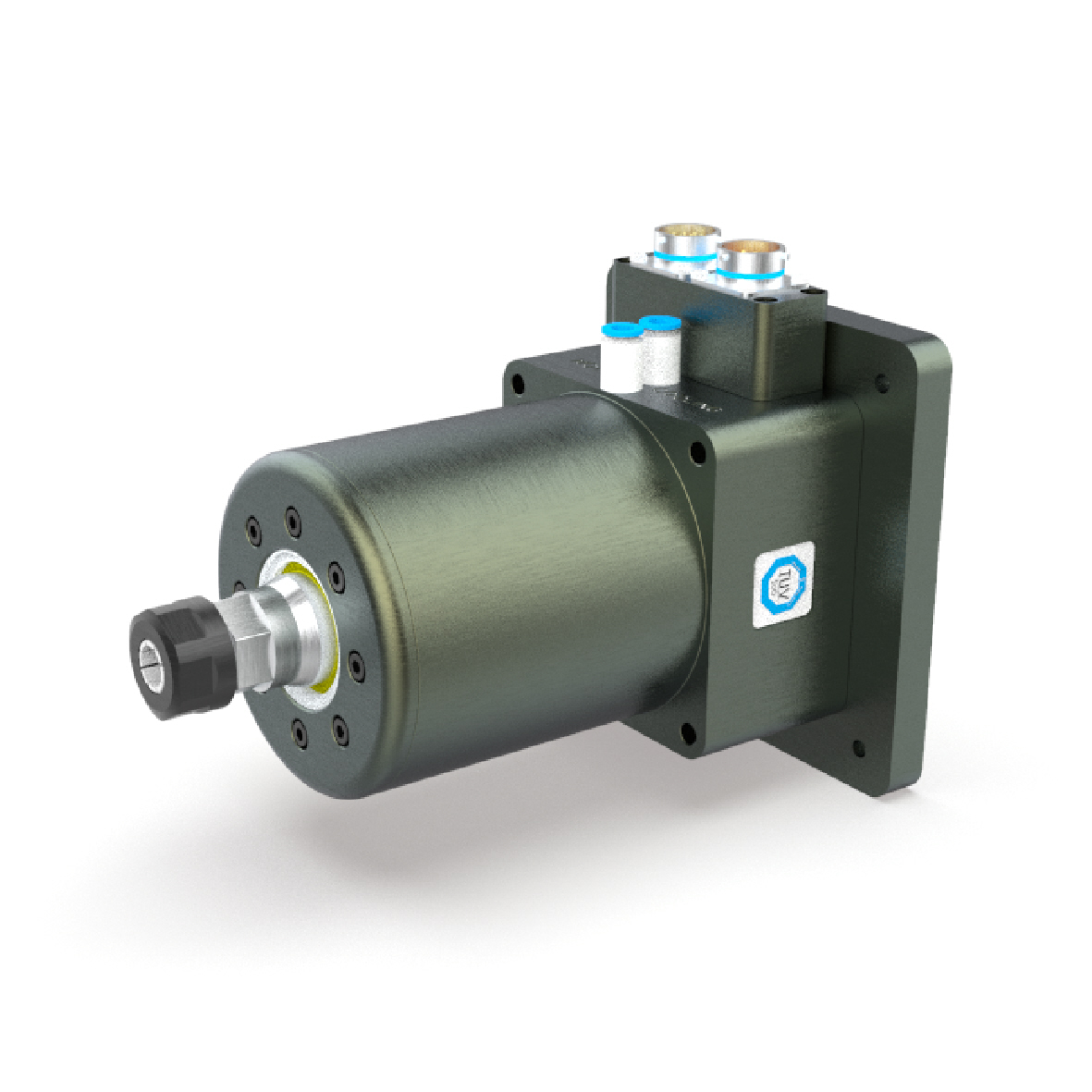

SM0605

SM0605 High-Torque, Robotic Servo Spindle The PushCorp SM0605 high-torque servo spindle is an ideal solution for robotic, material-removal applications such as: Robotic…

Learn More

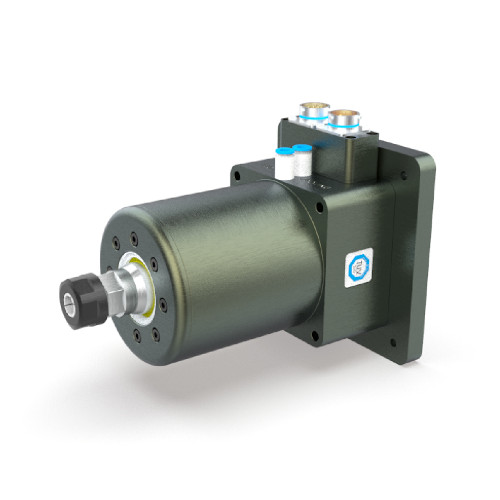

SM0612

SM0612 High-Torque, Robotic Servo Spindle The PushCorp SM0612 high-torque servo spindle is an ideal solution for robotic, material-removal applications such as: Robotic…

Learn MoreServo Motor Amplifiers

AKD2G

AKD2G Servo Amplifier The AKD2G is manufactured by Kollmorgen and is PushCorp’s next-generation amplifier. This servo amplifier will power, provide…

Learn More

S724

S724 Servo Amplifier The S724 is manufactured by Kollmorgen and is used to power our Servo Spindles. This amplifier powers…

Learn More

Control Cabinets

Ethernet IP UL Certified Control Cabinet The PushCorp S724 Control Cabinets provide a highly integrated, easy-to-use solution to controlling PushCorp…

Learn More