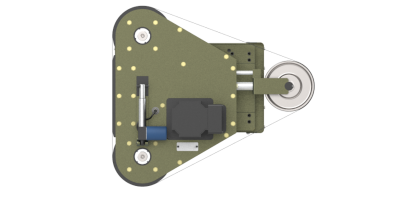

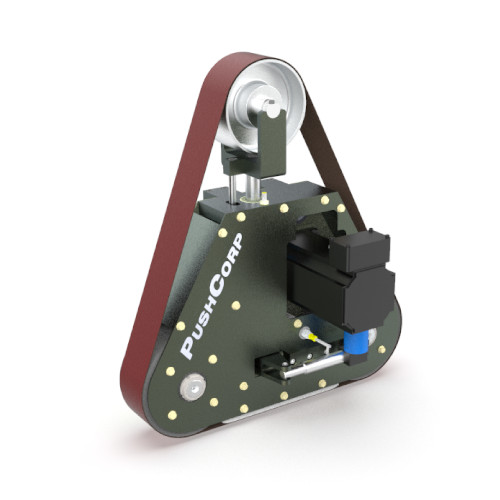

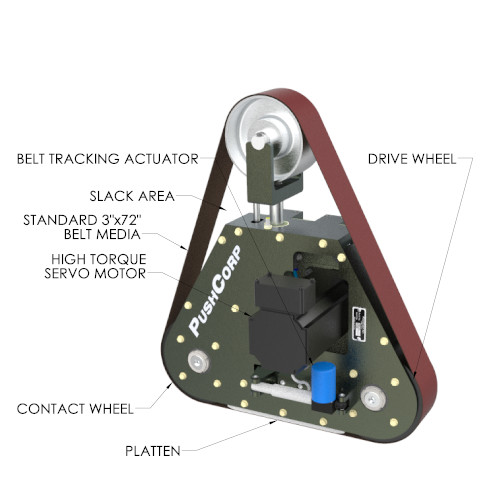

RBS372 Series

Robotic Belt Sander

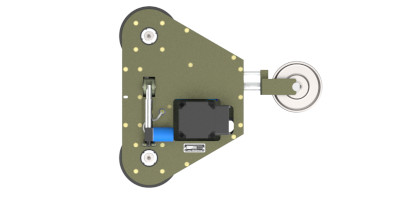

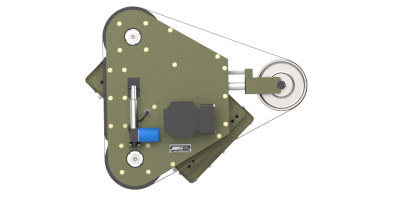

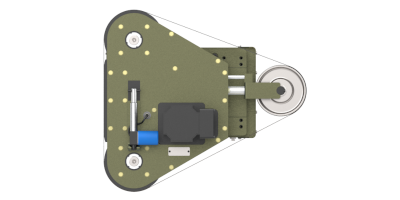

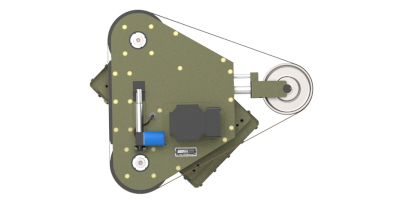

The PushCorp RBS372 Robotic Belt Sander is an ideal solution for belt sanding applications. It features a 72 inch long belt for long, continuous sanding applications. The RBS372 has been designed from the ground up as a mid-sized belt sanding unit with many unique features. The RBS372 may be used to sand in three different ways - on its large steel platen, on the 7 inch (178 mm) contact wheel, or in the slack area of the belt media. Two important features of the RBS372 Robotic Belt Sander are the high-torque servo motor and timing belt drive. The timing belt drive system provides a 1.2:1 reduction for increased power. The Robotic Belt Sander also includes pneumatic belt media tensioning and electronic belt media tracking to enable safe, remote operation.

The RBS372 is designed to mount on the AFD1240 and AFD92 force compliance devices. It may also be ordered with an optional stand with built-in force compliance. This turns the RBS372 into a passive backstand with a platen. The AFD stand includes a table-top AFD81 and a control box, which houses the amplifier and controls for the RBS372's motor and tracking actuator.