Robotic Drilling

Applications

Robotic Drilling

Say Goodbye to the Drill Press!

PushCorp force compliance devices and servo spindles are a must-have for robotic drilling applications. Without it, position-based drilling is extremely difficult to automate. A robot moves from point A to point B without any regard for the amount of force it is applying. So, as the drill bit wears, the robot does not know to slow down. As a result, a dull drill bit will not have time to cut the material. Therefore, the bit will "plunge" through soft material and leave an undesirable finish. For harder materials, the drill bit will break. Additionally, it is difficult for robots to move in a straight line, which will result in a crooked hole.

Conversely, force-based drilling makes it easy to account for the wear of the drill bit. With process development, a force is set that will cut the material at a desirable rate. Then, as the bit wears, the cut time will increase. This time can be monitored in the program and used as a trigger to perform a robotic tool change. Because the force compliance device has a linear stroke, it provides a motion that is similar to a drill press. This ensures a straight cut every time.

Robotic Drilling Aluminum

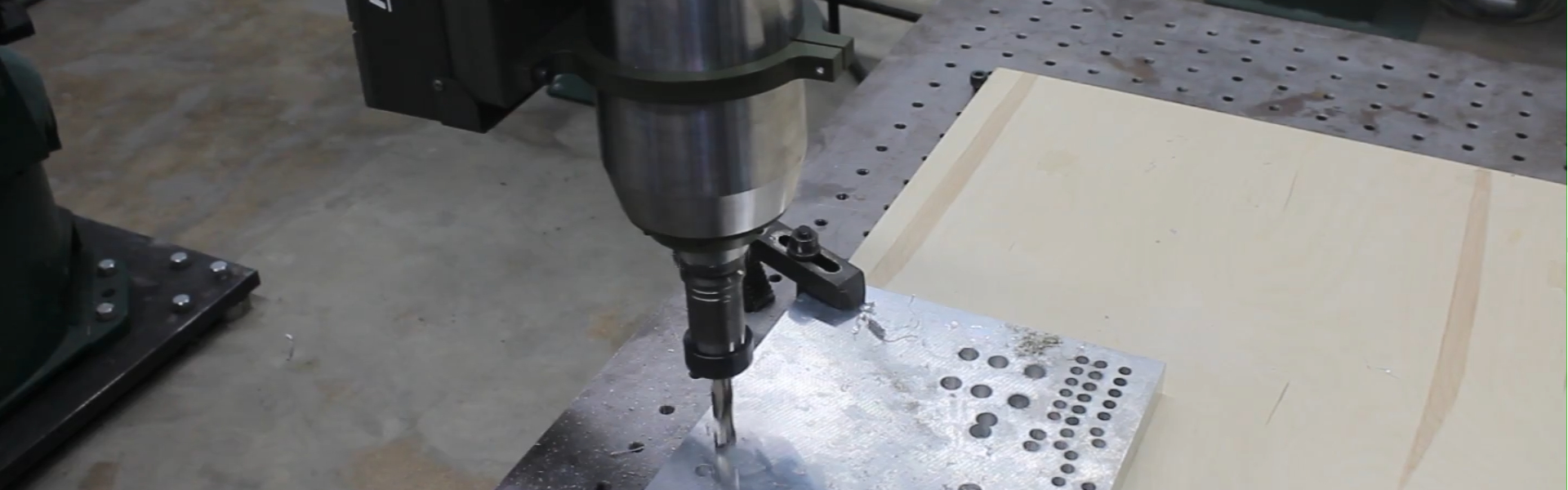

As an illustration, this video shows how effortless drilling can be. In fact, a robot paired with a PushCorp heavy-duty servo spindle is just what you need to automate your manual, material-removal application.

This video showcases our STC1015 and AFD620. Together, they are able to drill consistent, straight holes with ease.

We recommend using Walter Drilling Abrasives to ensure you can achieve the best results when automating your drilling applications.

Application Engineers With the Experience to Help You Succeed

Our application engineers have years of experience and can help recommend the right process equipment for your project. If you are new to integration or this is your first material-removal application, we are here to help. For more robotic, material-removal videos, make sure to check out our content below.

PushCorp Robotic Drilling

What Are You Waiting For? Get in Touch With Our Application Engineers Today! With 1000’s of systems sold, we have the equipment needed to make your project a success. Our application engineers are ready to learn about your process and help recommend the right products for your robotic surface finishing system.

With 1000’s of systems sold, we have the equipment needed to make your project a success. Our application engineers are ready to learn about your process and help recommend the right products for your robotic surface finishing system.