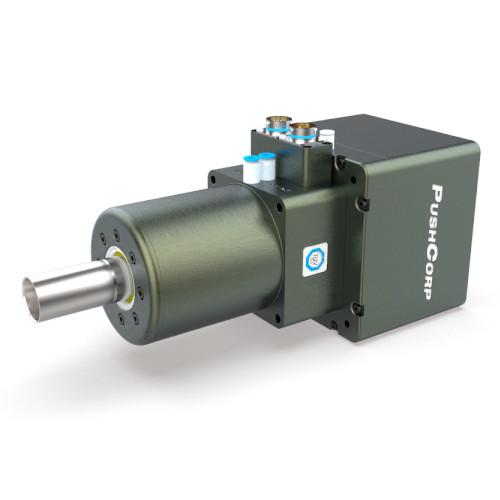

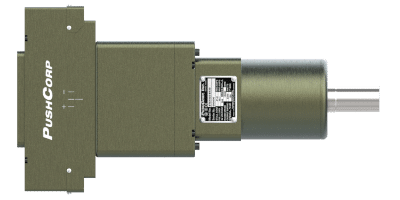

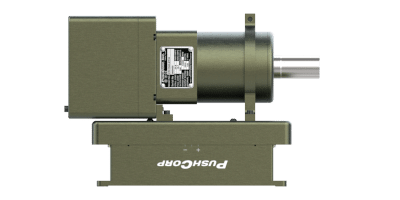

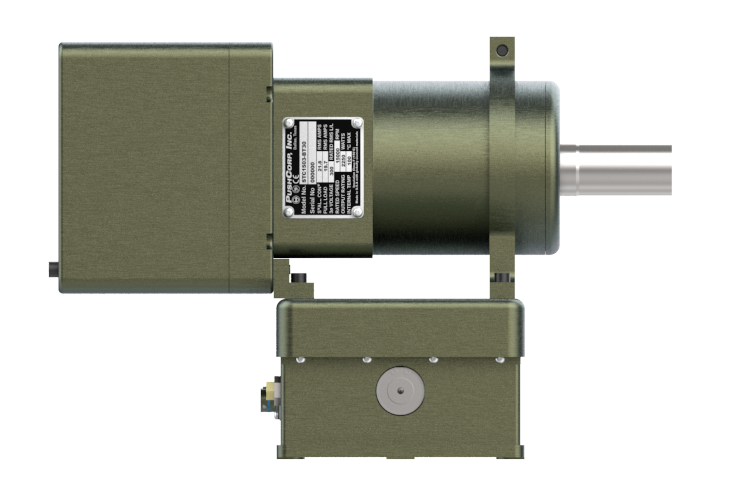

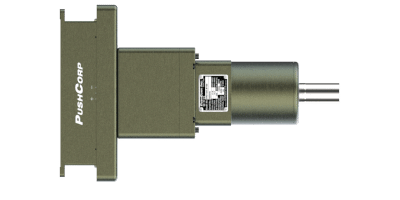

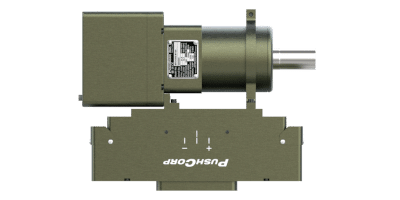

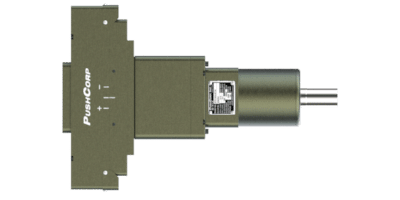

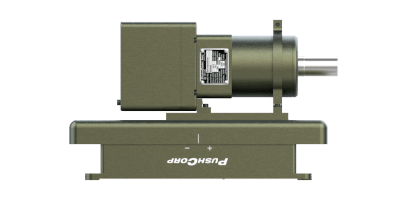

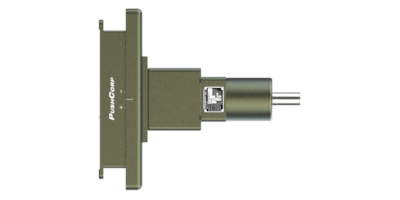

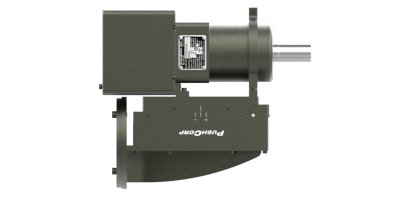

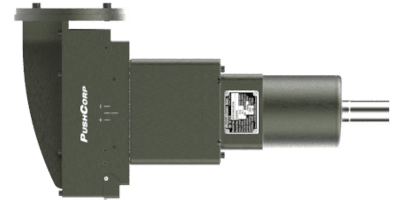

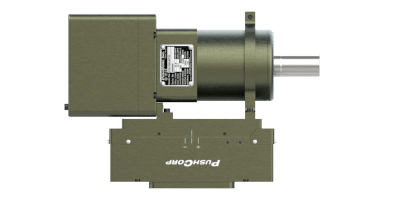

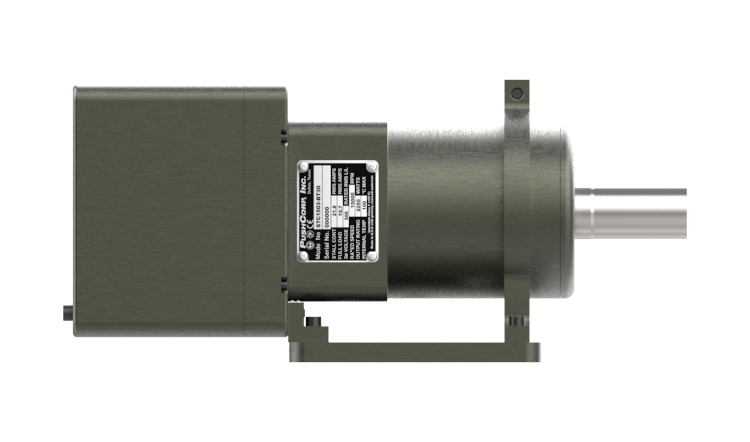

STC1503-BT30

The Kollmorgen S724 amplifier powers the servo spindle, as well as provides analog speed control and digital I/O. This can be ordered on its own or integrated into a UL certified control panel.

Features

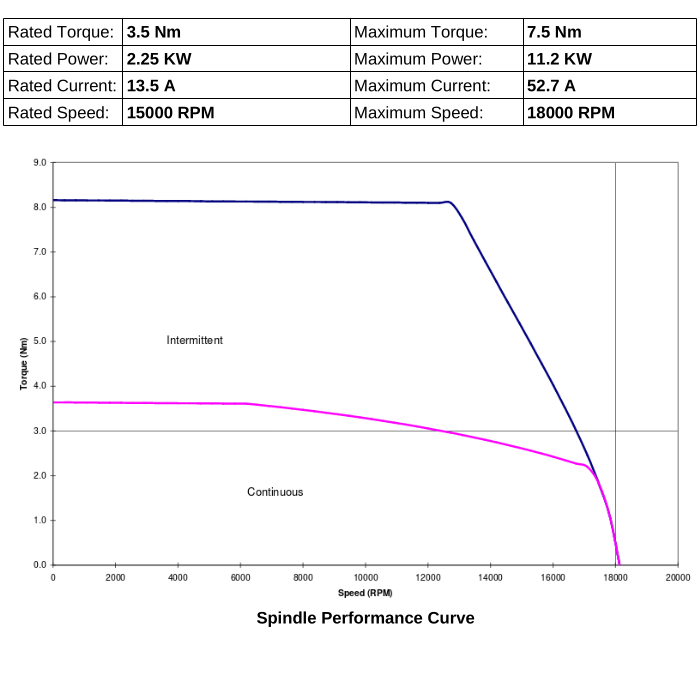

- 3.0 horsepower [2.2 kW] servomotor (Liquid Cooling Required)

- 15,000 maximum RPM

- Fully adjustable and reversible speed

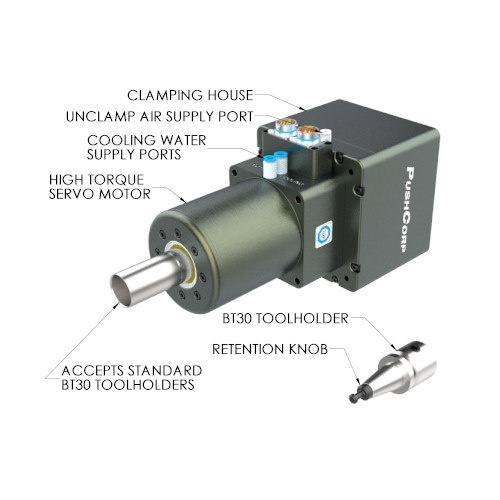

- Uses standard BT30 Toolholders

- Sealed bearings for long service life

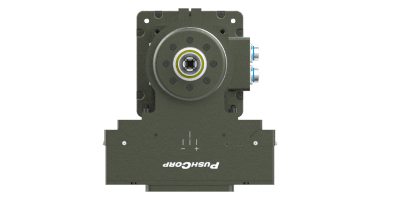

- PushCorp proprietary high-speed shaft seal

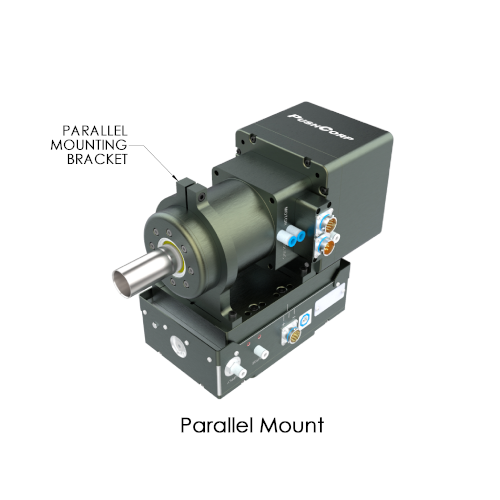

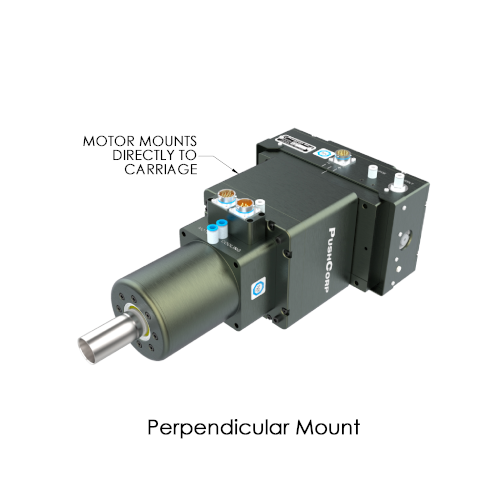

- Mounts directly to PushCorp Active & Passive Compliant tools

- Fail-safe pneumatic Toolholder release

- All fittings, fasteners, and threaded holes are METRIC

SPECIFICATIONS

| Model | STC1503-BT30 |

| Power | 3.0 hp [2.2 kW] |

| Continuous Stall Torque | 2.57 lb.-ft. [3.5 Nm] |

| Speed Range | 60-15,000 RPM |

| Speed Regulation | ±5% (Reversible) |

| Tool Weight | 28 lb. [12.7 kg] |

| Cooling | Liquid |

| Required Toolholder | BT30 |

| Retention Knob | Parlec 3003TRK or equiv. |

| Clamping Supply Air | Dry, Non-lubricated 90 psi [6.2 bar] Minimum 100 psi [6.9 bar] Maximum |