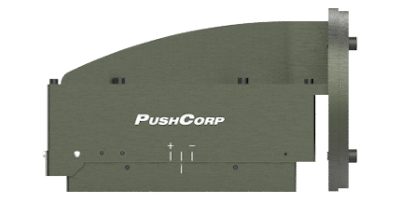

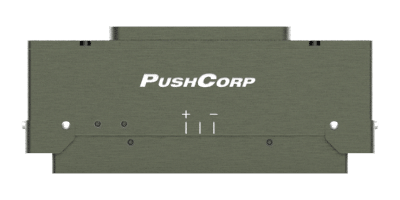

AFD310

You can see the AFD310 in action on several of our YouTube Videos, including the Weld Spatter Removal Application on this video.

Features

- Quick setup

- Consistent force regardless of orientation

- Automatic acceleration compensation

- Automatic payload weight measurement

- Force can be varied based on slide position

- 60 lbf [267 N] maximum compliant force

- 0.8 in [20 mm] Linear compliant stroke

- Fast mechanical response

- All fittings, fasteners, and threaded holes are METRIC

SPECIFICATIONS

| Model | AFD310 |

| Max Force | 60 lbf [267 N] |

| Force Resolution | ±0.2 lbf [±1.0 N] |

| Max Payload Weight | 60 lbs [27.2 kg] |

| Weight | AFD310-1: 17 lbs [7.7 kg] AFD310-2: 12 lbs [5.4 kg] |

| Compliant Stroke | 0.8 in [20 mm] |

| Supply Air | Dry, 5µm Filtered, Non-lubricated, 80-90 psi [5.5-6.2 Bar] |

| Technical Specification Packages | ||

|---|---|---|

|

AFD310-1 | Download Technical Files |

|

AFD310-2 | Download Technical Files |