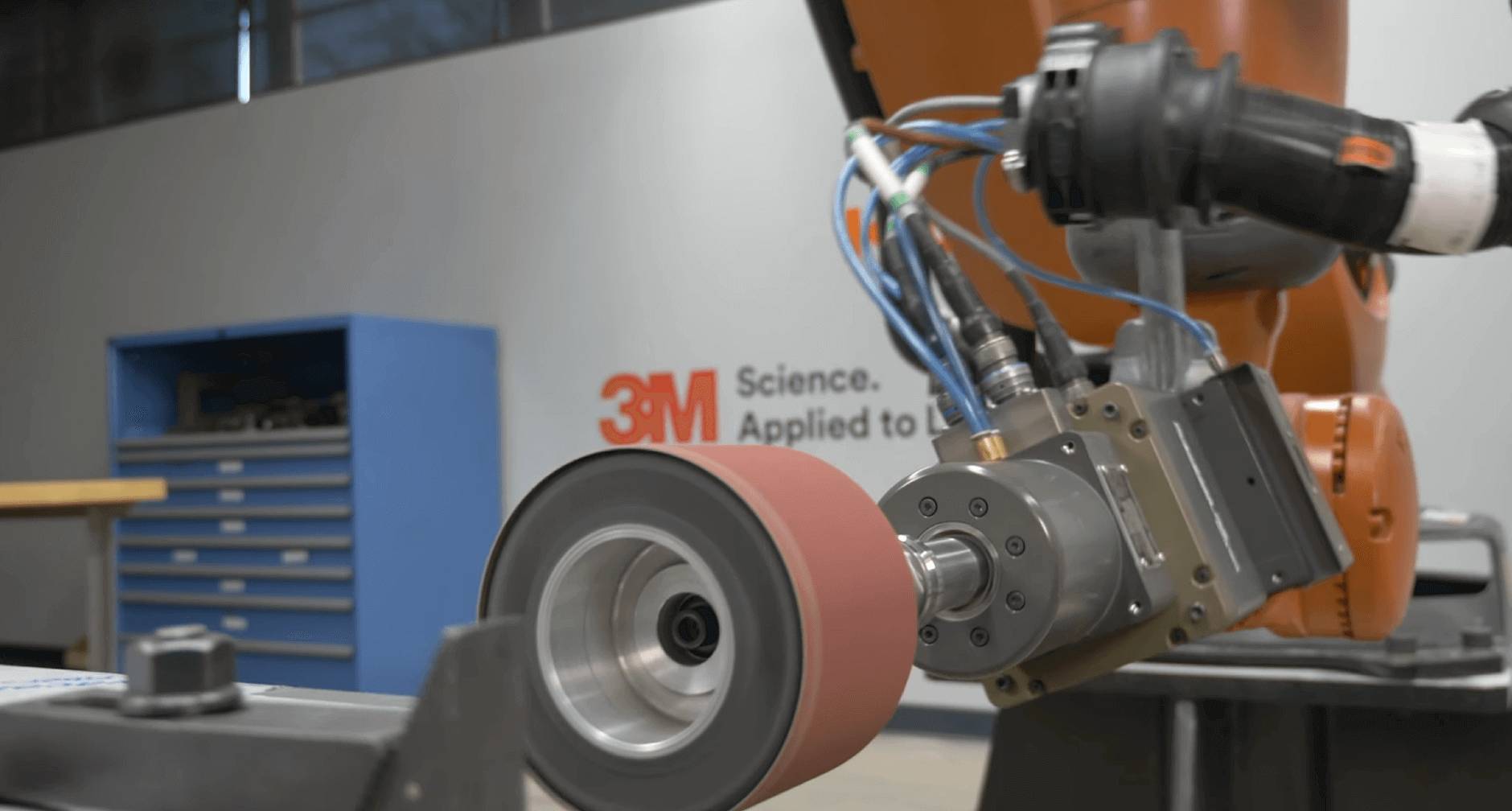

Let’s talk about your application needs.

Whether you’re exploring automation of material removal for the first time or upgrading your current process, our team is here to help you find the right tools and support to succeed.

Discuss with our engineers to get started with a demo, application review, or expert consultation.