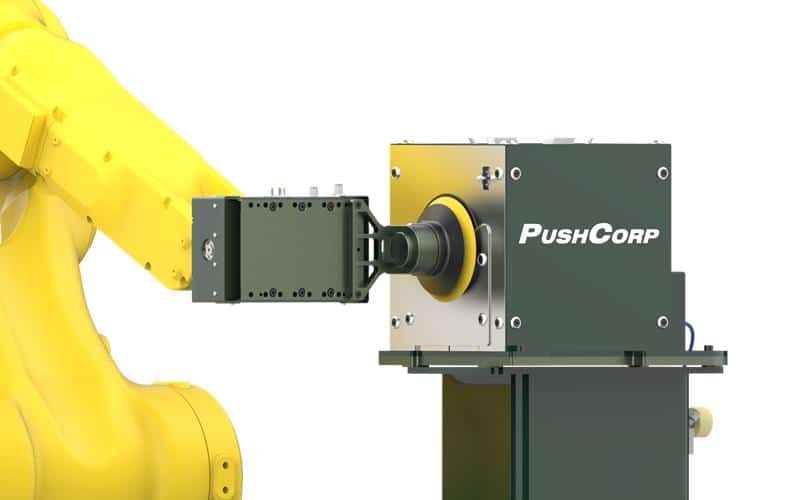

Automated Sanding Applications

Sanding is often a crucial step of the manufacturing processes for many products. While it has typically been done by hand, manual sanding has proven to be time-consuming, complex, and repetitive. Human error, operator fatigue, and differences in finishing techniques between operators are some of the problems of manual sanding. Even the same professional may struggle to maintain similar levels of sanding quality throughout the course of a shift. This makes sanding an ideal process for automation.

Automated sanding improves consistency and quality and allows for better allocation of human resources to more productive tasks. However, even automated sanding and refinishing are not without problems, ranging from manually changing sanding pads during production runs to overall inconsistencies and quality control issues.

So, how can you overcome the biggest challenges facing your robotic sanding processes?