Top 5 Sanding Automation Problems (and How to Solve Them)

Many SMMs explore sanding automation to ease labor strain, improve quality, or reduce ergonomic risk. However, the moment they shift from manual to automated sanding,…

How To Make Metal Grinding Easy, Safe, And More Productive

Metal grinding is messy, inconsistent, and exhausting. Heat builds, discs clog, and what starts as a clean surface can end up uneven or burned before…

Solving the 5 Biggest Grinding Automation Challenges

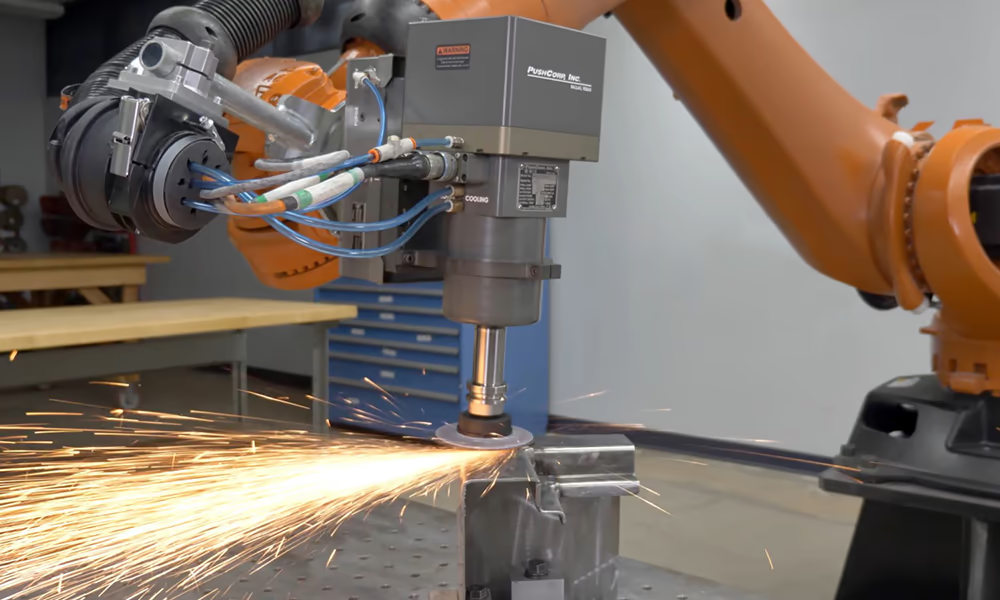

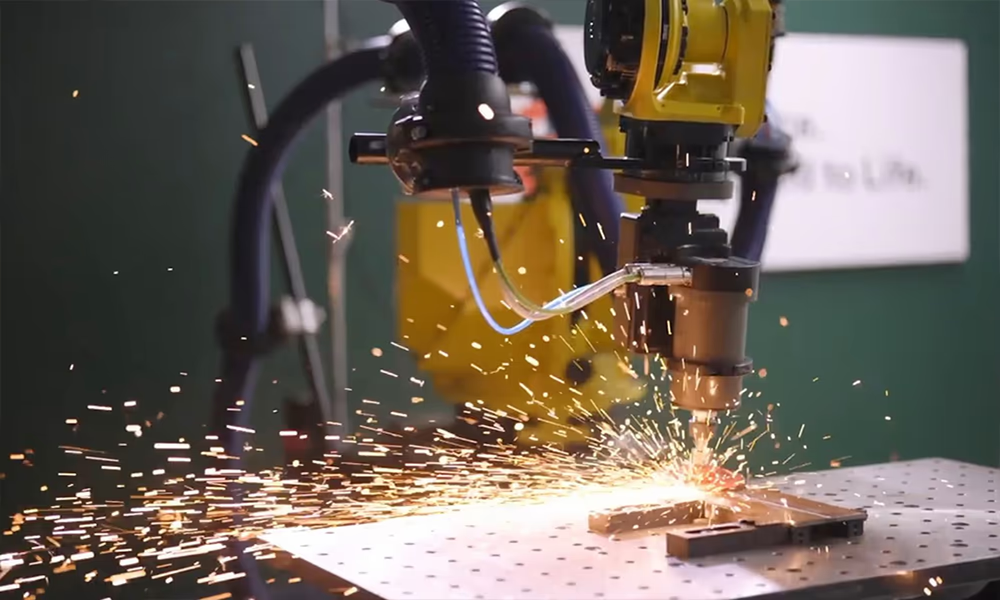

Grinding is tough work, so it’s no surprise manufacturers look to automate it. But automation only works when the process is stable and predictable. Projects…

Grinding Robots Market and Key Trends Manufacturers Must Watch

If you can’t hire enough grinders, keep finishes consistent, or hit ship dates, you’re not alone. Manual grinding is struggling to keep pace with modern…

Material Removal Cobots Replace Risk with Consistency

Grinding, sanding, and weld removal often lead to part variation caused by human fatigue or uneven pressure. Material removal cobots change that. These collaborative robots…

Robotic Grinding Costs Breakdown In Real World Manufacturing

Grinding is one of the toughest jobs on the production floor. It’s loud, dirty, and physically demanding. Even small changes in pressure or angle can…

Evaluating a Robotic Polishing Project

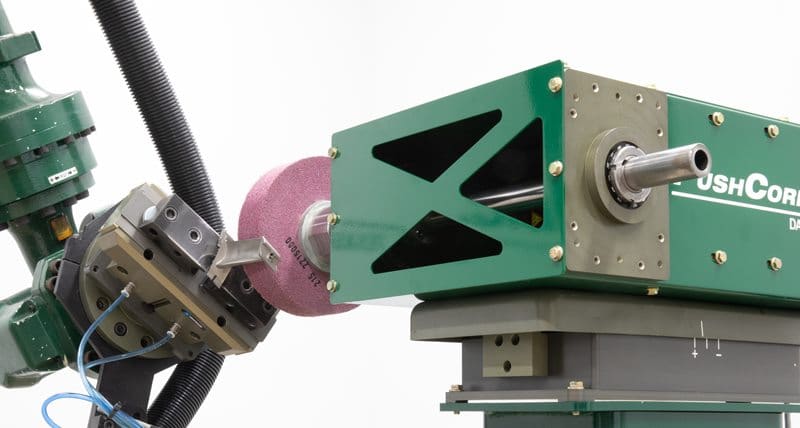

One of the biggest benefits of robotic automation is improved consistency. Robots follow highly repeatable motion paths, which means robotic processing avoids the variability seen…

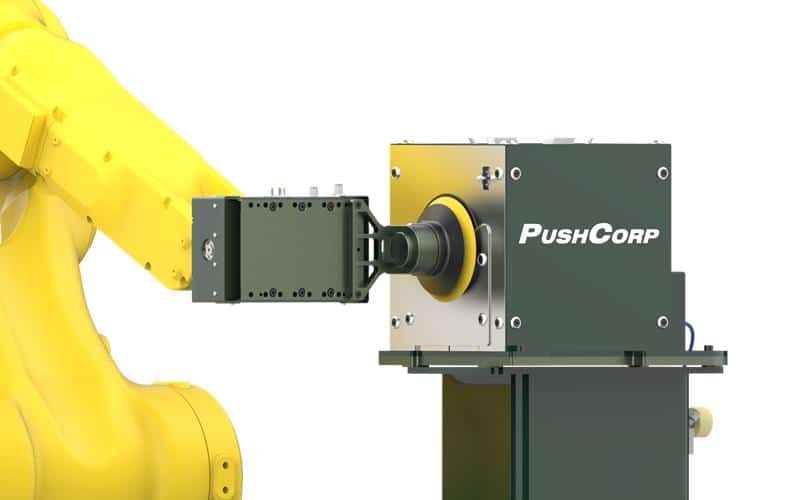

Automation for All: How PushCorp’s XSeries Can Help Bring Robotic Material Removal to Every Shop

For decades, robotic automation has been dominated by large manufacturers with the resources to build custom robotic systems. But today, automation is no longer just…

10 Insider Tips Every First-Time FABTECH Attendee Needs to Know

So, you’re heading to FABTECH for the first time—congratulations! Whether you’re a seasoned pro in the manufacturing world or just getting your feet wet, attending…

Achieving a Superior Brushed Metal Finish on Brass Door Handles: Techniques and Tools

Finishing is one of the most critical steps in the manufacturing process, as it directly influences the perception and quality of the end product. Whether…

Automated Sanding Applications

Sanding is often a crucial step of the manufacturing processes for many products. While it has typically been done by hand, manual sanding has…

The Advantages of Robotic Deflashing

When plastics or metals are molded, forged, or cast, excess material from the process may remain attached to the part that was just created. This…