Technology Overview

Robotic Weld Shavers

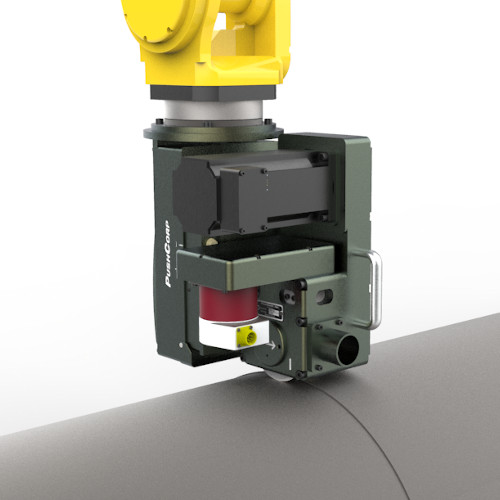

The SWS100-3.7 and SWS100-7.2 robotic weld shavers attach directly to our compliant, end-of-arm tools. The robot moves the weld shaver along the weld bead with the guide wheels straddling the weld while the compliant tool maintains a controlled force against the part surface to maintain contact. The robot’s programmability and large work envelope allow both straight and curved welds to be reliably removed on flat or contoured parts.

SWS100-3.7 With Remote Adjust

SWS100-3.7 With Remote Adjust

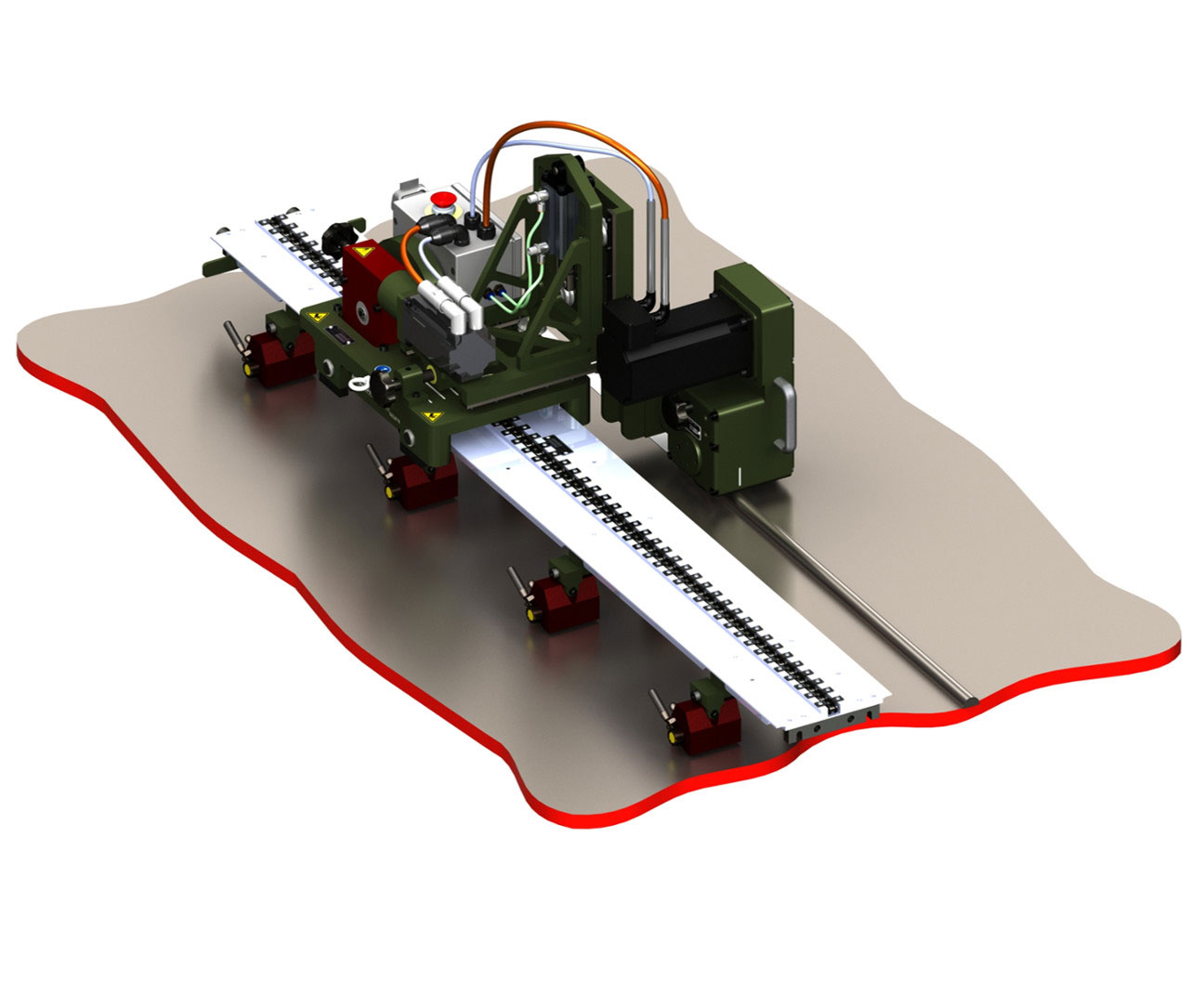

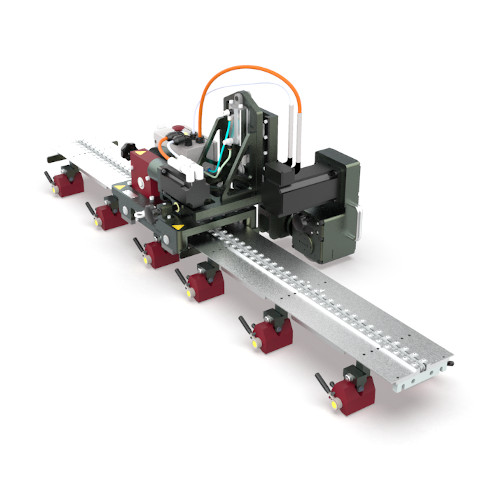

Track Weld Shavers

Originally developed for the shipbuilding industry, the PushCorp Track Weld Shaving system is a non-robotic system designed to remove long, linear welds quickly and easily. This system incorporates a SWS100-3.7 or SWS100-7.2, attached to a servo-driven carriage.

The carriage has built-in compliance and moves along the weld at a controlled speed on patent pending, high-capacity, sectioned track. This track is magnetically attached to the steel surface and is specially designed to handle the weight and cutting reaction forces in any orientation — even upside down! It manages all this, yet still remains flexible enough to conform to contoured surfaces with bend radii as little as 4 feet.

All this, combined with an intuitive control console, allows this technology to remove hundreds of feet of weld, cost-effectively and with little chance of worker injury.

Track Weld Shaving

TWS91

TWS91 Tracked, Weld-Shaving System The PushCorp TWS91 is an automated solution for the rapid removal of weld beads above a panel surface….

Learn MoreRobotic Weld Shaving

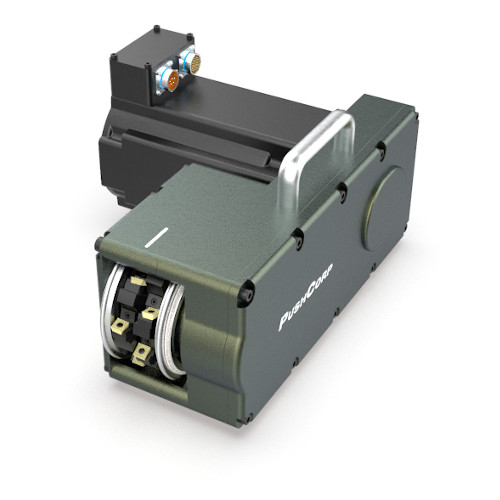

SWS100-3.7 Series

SWS100-3.7 Series Servo Weld Shaver The PushCorp SWS100-3.7 Servo Weld Shaver has the power and capability to transform a largely varying profile…

Learn More

SWS100-7.2 Series

SWS100-7.2 Series Servo Weld Shaver The PushCorp SWS100-7.2 Servo Weld Shaver has the power and capability to transform a largely varying profile into…

Learn More