Take the Grind out of Grinding

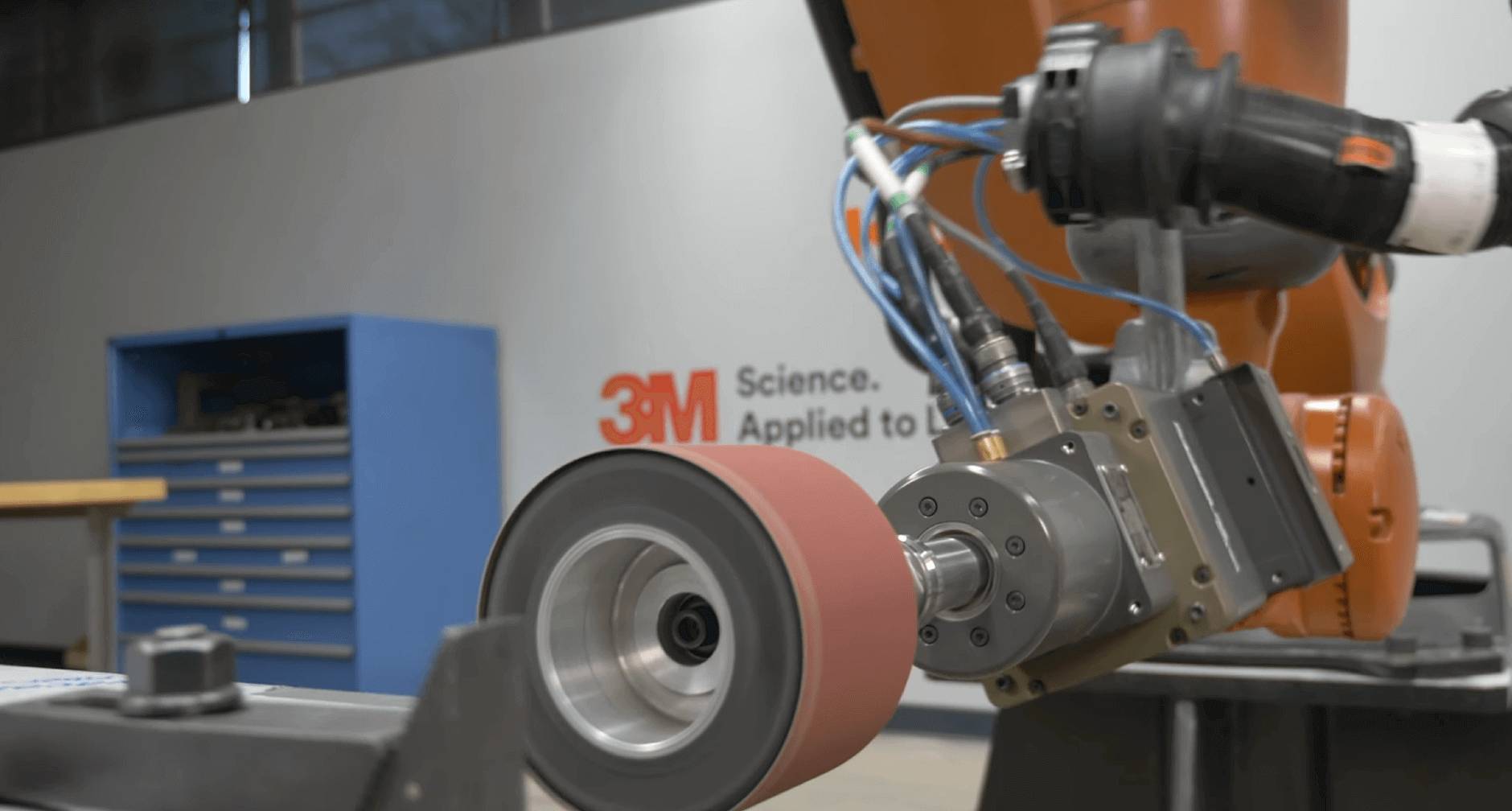

From weld removal to heavy beveling, our robotic tools deliver safer work environments, consistent finishes, and reliable performance shift after shift.

From weld removal to heavy beveling, our robotic tools deliver safer work environments, consistent finishes, and reliable performance shift after shift.

PushCorp GrindX™ automates the toughest grinding jobs, so your team can focus on the work that matters. Manual grinding is dirty, exhausting, and inconsistent. PushCorp GrindX™ solves these challenges by:

‟We had all these welders that were splitting their time between welding and grinding. After implementing the robotic solution, they were able to solely focus on welding… the entire shop saw a big boost in efficiency, morale, and throughput.”

Our engineers will help you configure the right PushCorp GrindX™ solution, de-risk your application, and validate results in our Demo Lab.

The XSeries Robotic Tooling Solutions line from PushCorp combines two robust technologies to create one powerhouse solution for robotic material removal

We have multiple quick-deploy product pairings to help you get up and running faster. These are common starting points, but after working directly with our engineers and derisking your application, your PushCorp GrindX™ solution may look a little different.

Our dedicated sales engineers are here to partner with you to ensure that you are getting the right equipment to do the job right the first time.

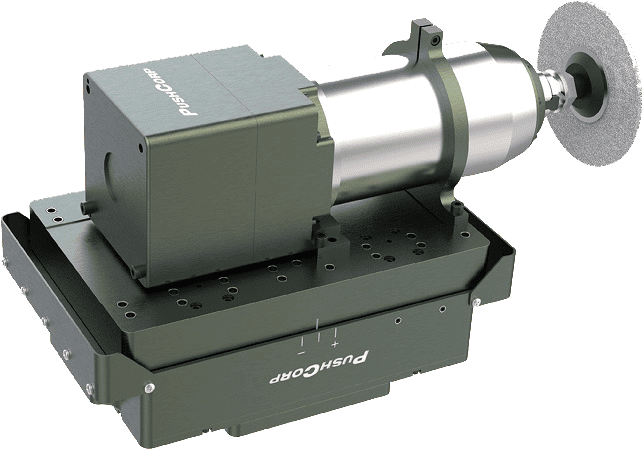

Built for cobots and smaller industrial robots, this setup is perfect for automating light grinding, sanding, deburring, and polishing applications.

Whether you’re finishing curved geometries or prepping edges on aluminum or stainless, this PushCorp GrindX™ combo delivers repeatable quality without operator fatigue.

When light-duty tools just won’t cut it, this PushCorp GrindX™ setup delivers the torque and force needed for grinding, sanding, deburring, or polishing larger and more complex parts.

This solution is engineered to take on demanding material removal tasks while adapting to curved or variable surfaces, automating tough jobs without compromising finish quality.

When your operation demands the most power and durability, this PushCorp GrindX™ solution delivers. Engineered for heavy-duty robotic grinding, it’s built to withstand impact loading, power through thick welds, and hold up to the harshest shop conditions, all while maintaining consistent finishes and minimizing rework.

This setup is ideal for manufacturers handling larger parts, structural steel, or any application where throughput, torque, and force output are critical.

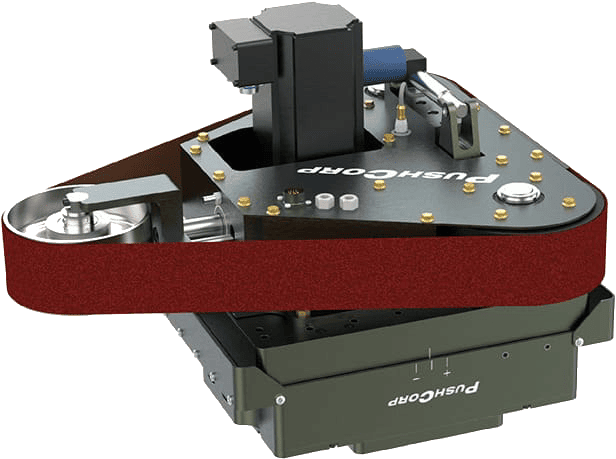

When surface area, part variation, or sanding duration become limiting factors, this PushCorp GrindX™ belt solution steps in. Built for continuous, high-force sanding, it adapts to part geometry while delivering powerful, repeatable results with minimal manual intervention.

Whether you’re finishing weldments, smoothing formed sheet metal, or preparing large structural parts, this setup provides the flexibility, force, and coverage needed to do the job safely and consistently.

Whether you’re exploring automation for the first time or upgrading your current process, our team is here to help you find the right tools and support to succeed.

Discuss with our engineers to get started with a demo, application review, or expert consultation.