Consistent Finishes, Made Simple

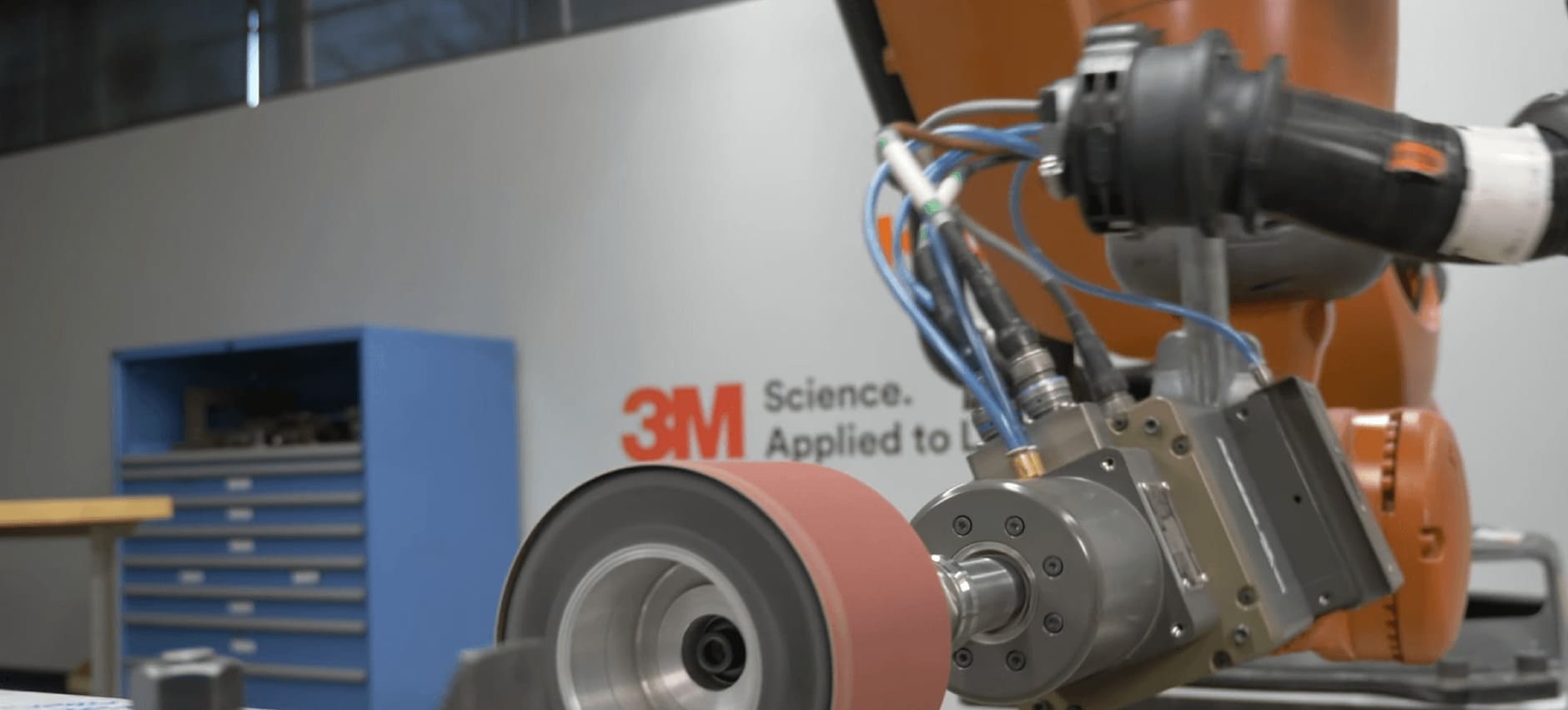

PushCorp FinishX™ automates surface finishing tasks for better consistency, improved safety, and faster turnaround without the mess, fatigue, or guesswork of manual polishing.

PushCorp FinishX™ automates surface finishing tasks for better consistency, improved safety, and faster turnaround without the mess, fatigue, or guesswork of manual polishing.

PushCorp FinishX™ automates polishing and finishing on metals like stainless steel and aluminum while saving time, reducing rework, and protecting your team from repetitive, physically demanding tasks.

Manual polishing is inconsistent, labor-intensive, and hard to scale. PushCorp FinishX™ solves these challenges by:

‟We had all these welders that were splitting their time between welding and grinding. After implementing the robotic solution, they were able to solely focus on welding… the entire shop saw a big boost in efficiency, morale, and throughput.”

Our engineers will help you configure the right PushCorp FinishX™ solution, de-risk your application, and validate results in our Demo Lab.

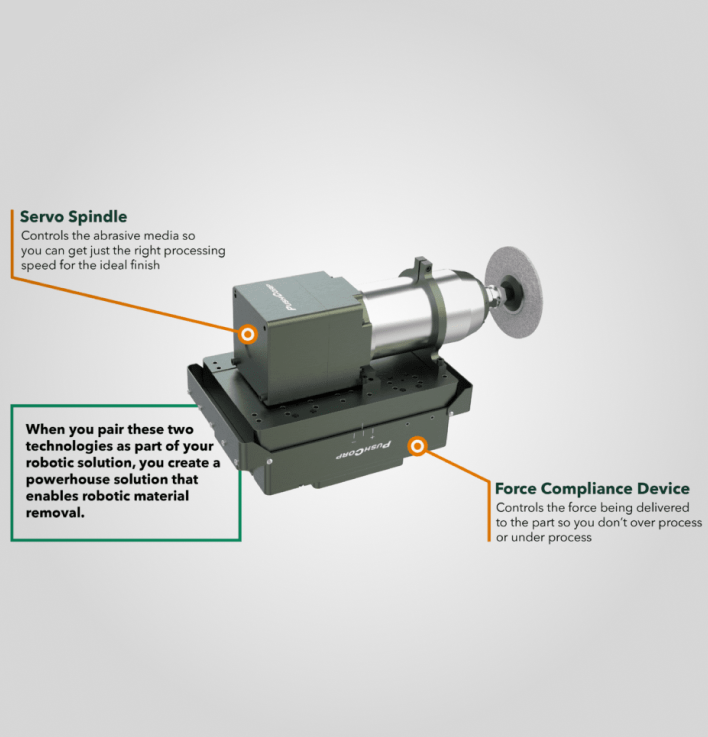

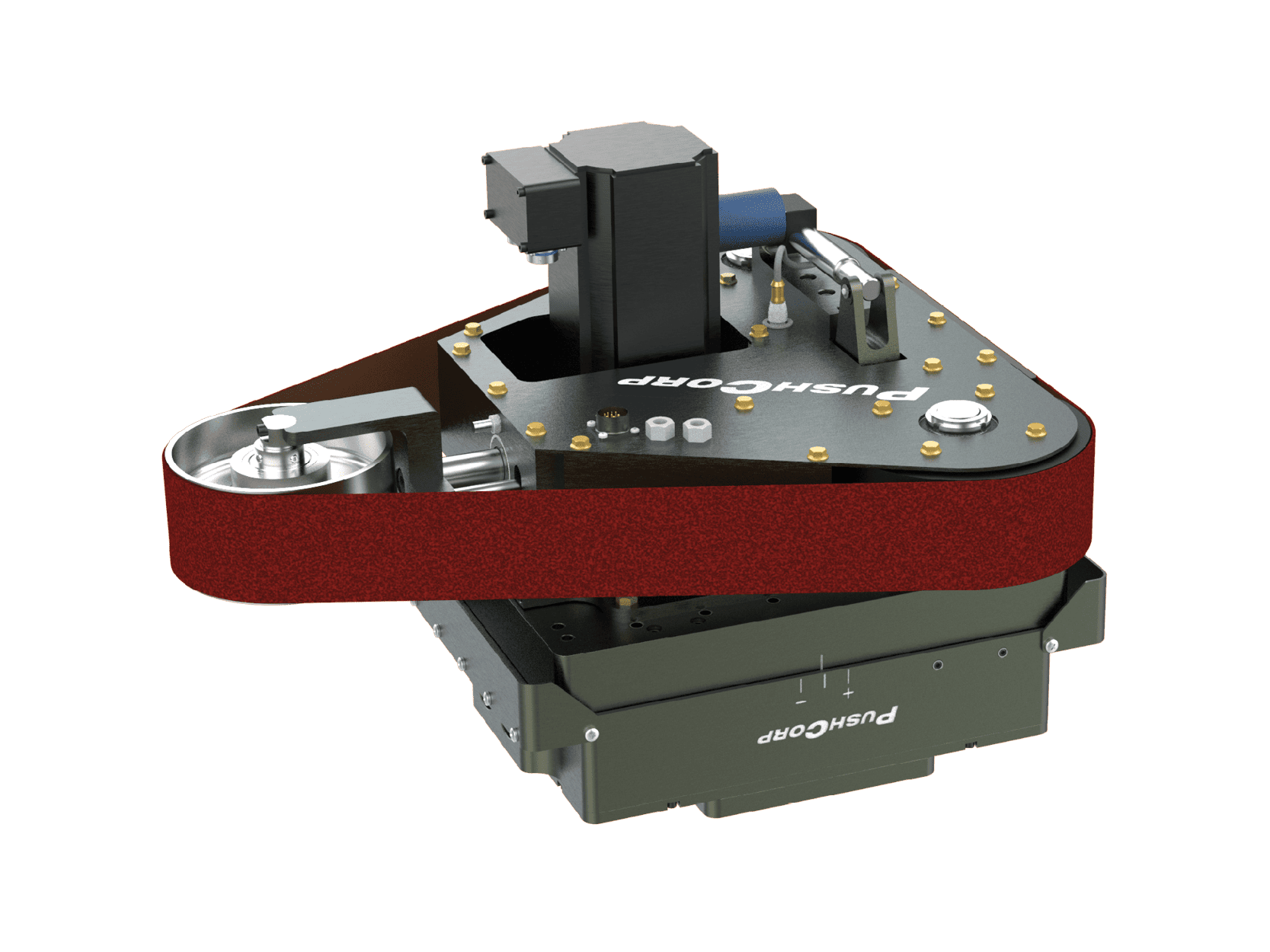

The PushCorp FinishX™ solution pairs two proven technologies to create one powerful system for automated surface finishing:

Together, these components simplify robotic finishing while delivering repeatable results and long-term reliability.

We offer proven product pairings to get your cell up and running faster. Your final setup may vary depending on your goals, but these configurations are excellent starting points.

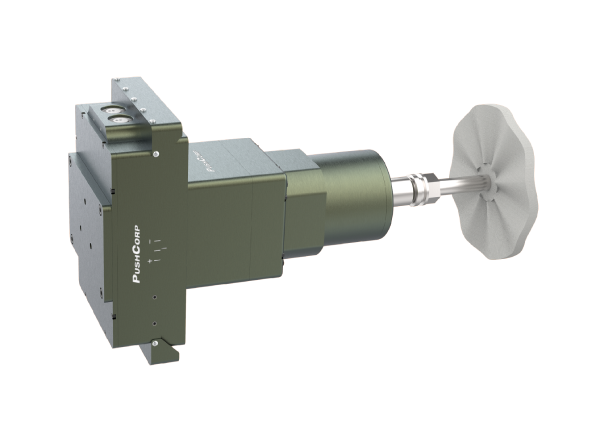

This PushCorp FinishX™ pairing delivers the consistent, directional polish required for a #4 finish on stainless steel or aluminum. Ideal for architectural metals and sheet goods, it’s a versatile solution that balances torque, speed, and precision in one clean setup.

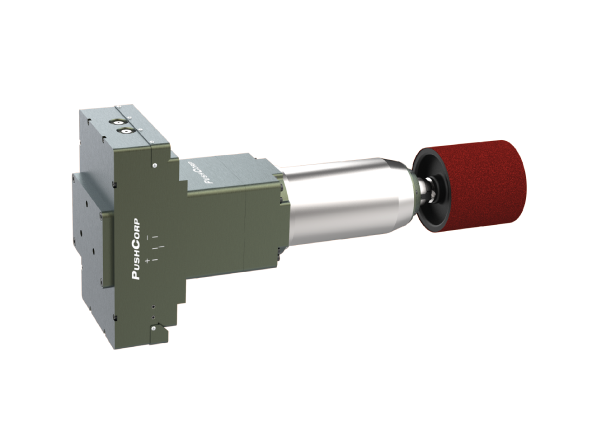

This heavy-duty PushCorp FinishX™ pairing is built for demanding polishing jobs that require high torque, precision, and consistent pressure. It’s the go-to setup for creating flawless mirror finishes on complex parts or large surfaces.

This rugged PushCorp FinishX™ configuration is built to handle aggressive wheel-based brushing tasks on flat or contoured parts. Whether you’re finishing stainless panels or blending edges, it delivers consistent results with the torque and control needed for production-grade results.

When you need straight-line brushed finishes across long or flat surfaces, this belt-based PushCorp FinishX™ configuration delivers. Built for high-torque performance and continuous-duty operation, it excels in graining, de-scaling, and cosmetic prep for large metal parts.

Whether you’re exploring automation for the first time or upgrading your current process, our team is here to help you find the right tools and support to succeed.

Discuss with our engineers to get started with a demo, application review, or expert consultation.