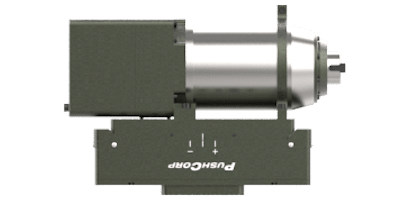

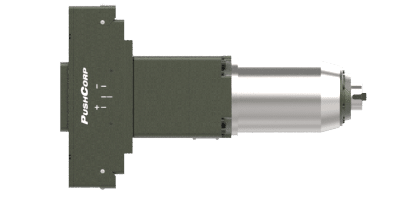

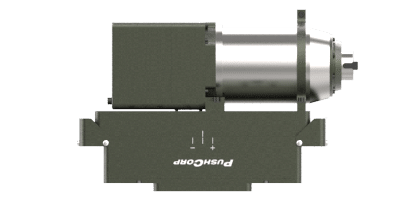

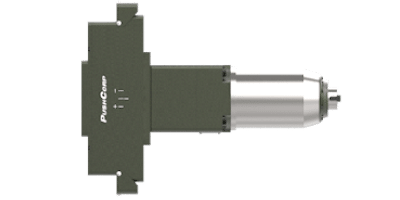

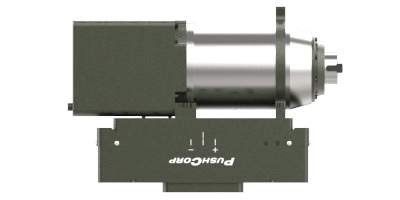

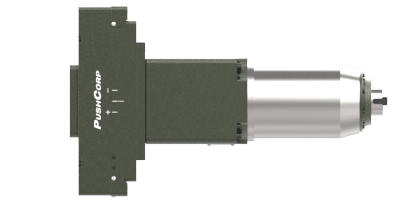

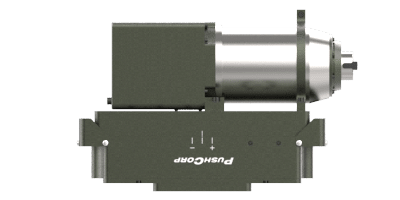

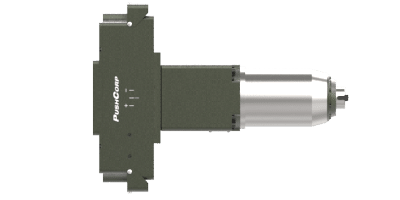

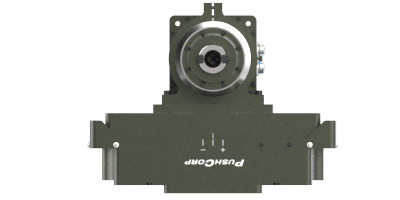

The STC1515 may also be mounted directly to the robot with no force compliance device. This opens the door for rigid applications such as routing and deflashing.

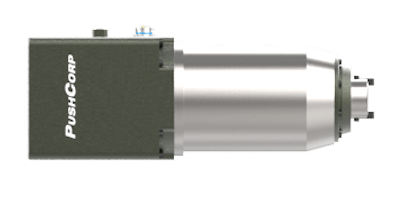

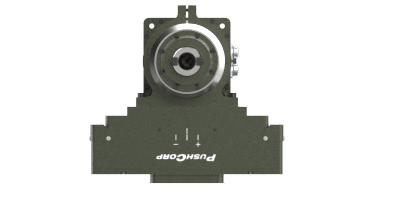

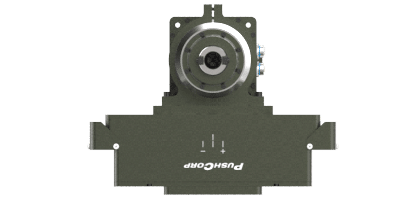

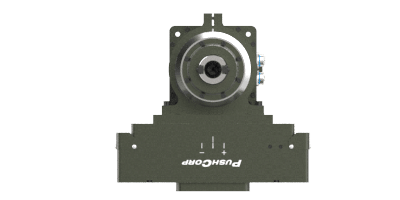

The motor shaft is configured to accept standard BT30 tapered toolholders. Customers can choose to use standard, off-the-shelf CNC tooling, as well as custom PushCorp toolholders. Together, these components allow for a wide range of abrasive disks, wheels, drill bits and cutting tools.

The STC1515 servo spindle comes standard with quick-change functionality. Simply supply 90 PSI to drop off a tool holder, then release the air pressure to pick up a new one with a fresh abrasive.

The Kollmorgen S724 amplifier powers the servo spindle, as well as provides analog speed control and digital I/O. This can be ordered on its own or integrated into a UL certified control panel.

| Model | STC1515 |

| Power | 15.0 hp [11.2 kW] |

| Continuous Stall Torque | 7.4 lb.-ft. [10 N·m] |

| Speed Range | 0-15,000 RPM |

| Speed Regulation | ±2% (Reversible) |

| Tool Weight | 65 lb. [29.5 kg] Dry |

| Cooling | Liquid |

| Required Toolholder | BT30 |

| Retention Knob | Parlec 3003TRK or equiv. |

| Clamping Supply Air | Dry, Non-lubricated 90 psi [6.2 bar] Minimum 100 psi [6.9 bar] Maximum |

| Technical Specification Packages | ||

|---|---|---|

|

STC1515 | Download |

|

AFD82-2 Parallel | Download |

|

AFD82-2 Perpendicular | Download |

|

AFD82-2 Parallel #2 | Download |

|

AFD92-2 Parallel | Download |

|

AFD92-2 Perpendicular | Download |

|

AFD92-2 Parallel #2 | Download |

|

AFD620-2 Parallel | Download |

|

AFD620-2 Perpendicular | Download |

|

AFD620-2 Parallel #2 | Download |

|

AFD1240-2 Parallel | Download |

|

AFD1240-2 Perpendicular | Download |

|

AFD1240-2 Parallel #2 | Download |

Frequently used components and accessories with the STC1515.

Toolholders PushCorp's spindles and force compliance devices enable manual,...

Contact PushCorp today to integrate the STC1515 into your robotic system.

Request a Quote