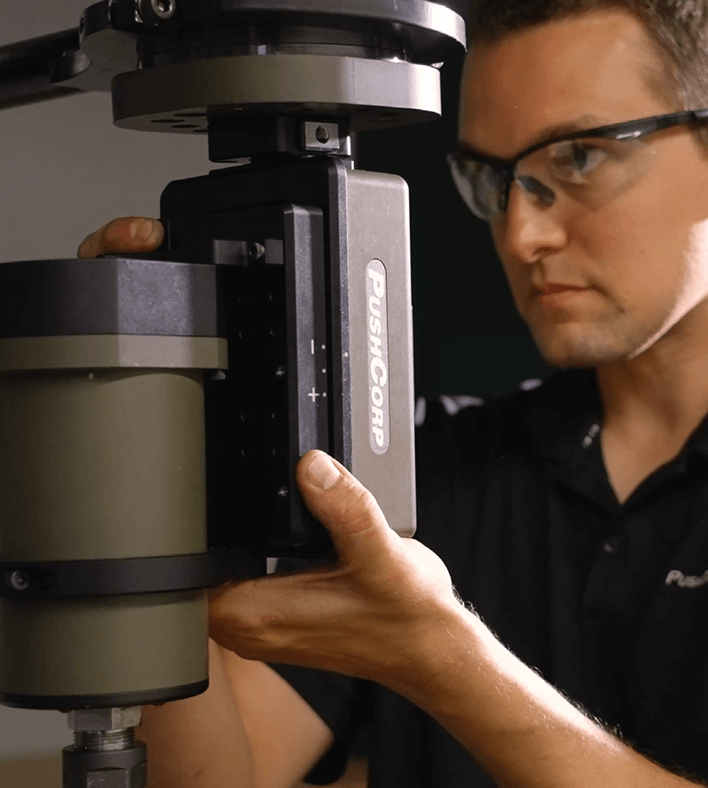

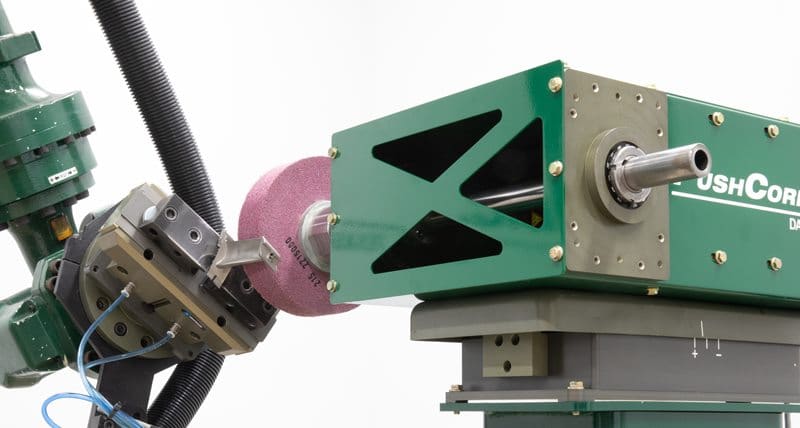

Rugged Material Removal Automation Built for Your Toughest Jobs

For over 30 years, manufacturers have turned to PushCorp when manual grinding, sanding, and finishing hold them back.

We understand the real challenges you’re facing: Skilled labor is hard to find. Productivity is unpredictable. And safety risks are always one step away.

That’s why we design rugged, easy-to-implement robotic tooling systems that deliver consistent results, without needing a robotics expert on your team.

When you work with PushCorp, you’re gaining a partner that helps you simplify complex work, improve output, and protect your team.