Remove Inconsistencies and Elevate Your Part's Finish

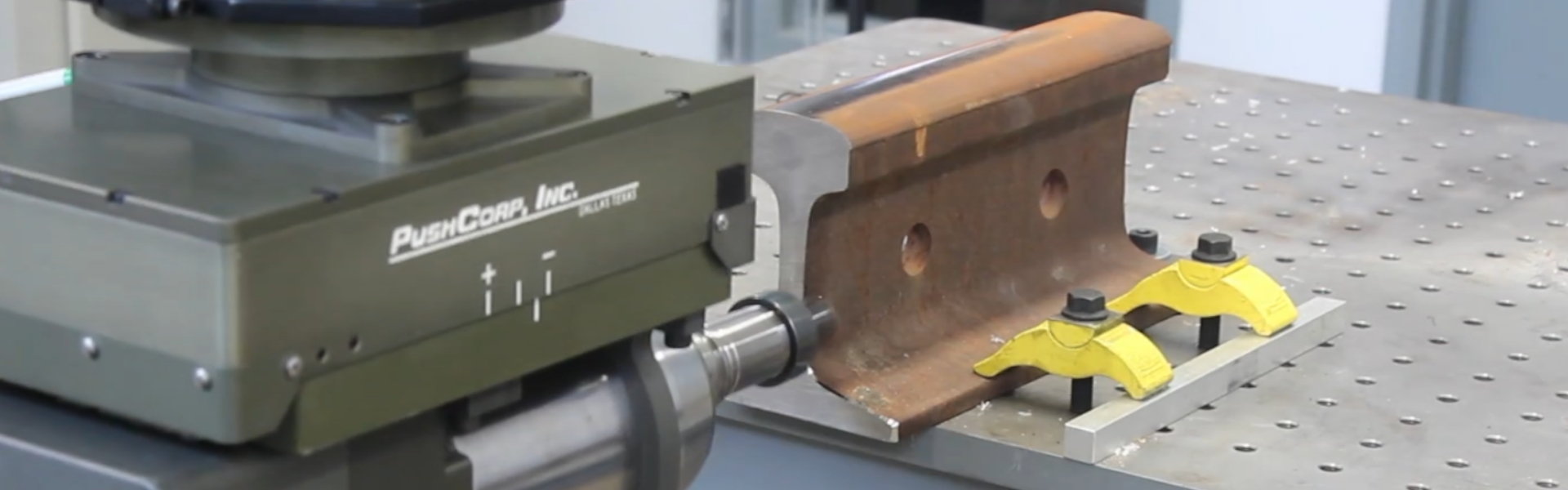

Robotic deburring is an application where PushCorp's EOAT equipment excels. Our precise force and constant speed end effectors account for part variability and abrasive wear. Therefore, manual processes can be automated easier than ever.

In non-automated finishing processes, operators rely on visual inspections. Not only is this a tedious process, but it leaves the finish completely up to the individual doing the inspection.

The skill level of these workers is extremely variable due to the high turnover in the industry. As a result, manually finished parts are inconsistent, being either over or under-processed. In addition to an inferior finish, non-automated processes use a higher volume of abrasives. For example, if the operator applies too much force, the abrasive media glazes over. Conversely, the abrasive will not re-fracture if too little force is applied. With an automated system, not only is the part quality significantly better, but abrasive life can increase by 200-300%.