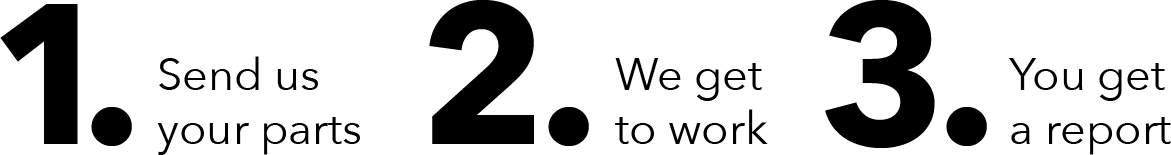

How Our Demo Lab Helps You Succeed

Step 1: Send Us Your Parts

Begin by shipping us the parts you want to automate for material removal. Whether you’re dealing with grinding, polishing, sanding, or any other material removal application, our experts are ready to dive in and develop a process for your specific needs.

Step 2: We Analyze and Refine the Process

Once your demo is scheduled, our team will work closely with your parts to identify the best combination of abrasives, tooling, equipment, and parameters. Over one week, we meticulously test and refine each aspect to ensure your process is optimized for efficiency and quality.

Step 3: Receive a Detailed Report

At the end of the demo, you’ll receive a comprehensive report outlining the recommended process, including all the data and insights gathered during testing. This report serves as a roadmap, whether you plan to implement the process in-house or hand it off to a system integrator.

RECOMMENDED: Collaborate On-Site with Our Engineers

To ensure everything is perfectly dialed in, we invite you to visit our lab and work side-by-side with our robotic application engineers. This collaborative step helps fine-tune the process in real-time, giving you confidence that your automation will perform exactly as expected.

Automation is more than just a solution—it’s a strategic advantage in the face of labor challenges. Our demo lab helps you refine automated processes that not only fill labor gaps but also enhance productivity, allowing your team to focus on higher-value tasks.

Consistent quality is critical to your success. Through our hands-on testing and expert recommendations, we ensure that your automated process is optimized for precision and reliability, helping you deliver high-quality results that meet the highest standards.

Our demo lab delivers process optimization through our recommendations in the final report. By refining each element, we can help you streamline operations, increase precision, and boost ROI. We provide actionable insights that allow you to stay competitive in evolving markets.

Ready to De-Risk Your Application? Request a Demo Now!

Solving Manufacturing Challenges Through Automation

Navigating Labor Gaps with Confidence: As labor shortages continue to impact manufacturing, automation is becoming essential to maintaining production efficiency. Our demo lab provides a crucial step in this journey, allowing you to develop and refine automated processes that can help fill labor gaps. By de-risking your approach in a controlled environment, you can confidently move forward with automation, knowing that your process is optimized for successful implementation.

Achieve Unmatched Quality: Consistent quality is vital for meeting customer demands and maintaining your competitive edge. Our demo lab helps you fine-tune every aspect of your robotic material removal process, ensuring uniform, high-quality finishes. With our expert insights and comprehensive testing, you can eliminate variability and deliver products that meet your exacting standards—every time.