Robotic Gate Removal

Applications

Gate Removal

Heavy-Duty Equipment Built to Last

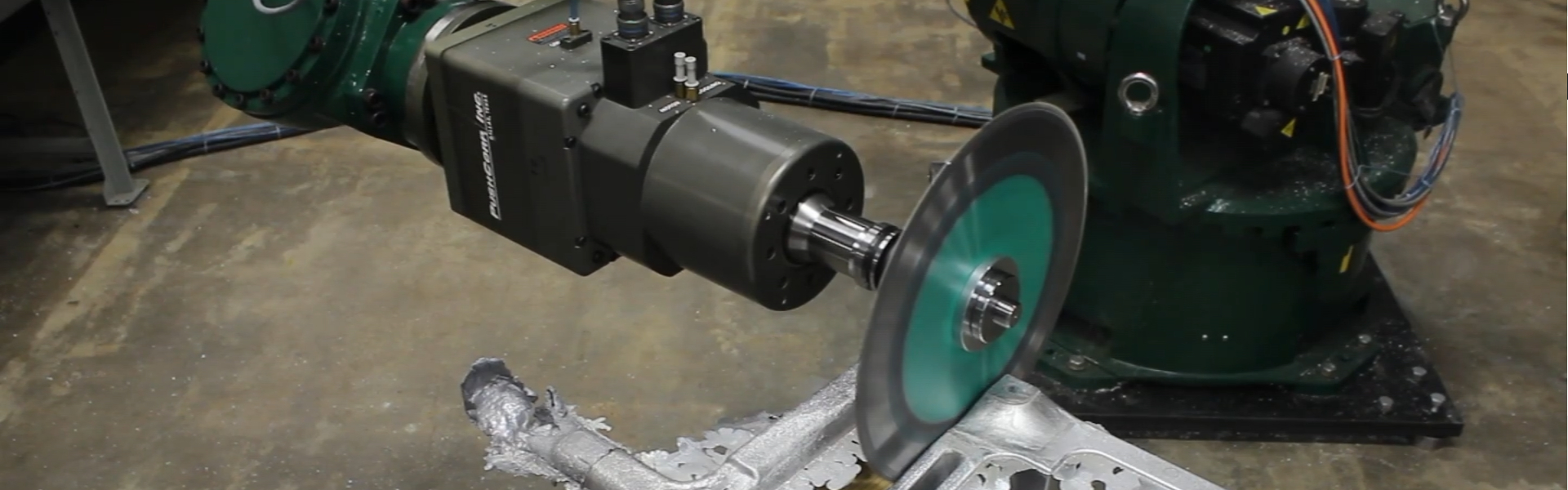

PushCorp servo spindles have been deployed around the globe to help automate robotic, gate-removal processes. Now, more than ever, foundries are focusing on providing safer work environments and higher quality parts. PushCorp's powerful and durable servo spindles are a perfect fit for these harsh environments and demanding applications.

Robotic gate removal typically requires the process equipment to be rigidly mounted. In this type of setup, the spindle is exposed to higher loading compared to grinding or sanding with compliance. Therefore, PushCorp has created a range of spindles for more strenuous applications. The STC1515, STC1015, and STC0612 feature heavy-duty bearings. These help the spindles withstand impact loading and radial forces, to help ensure long term, continuous usage.

Robotic Metal-Casting Cutoffs with Steel, Cast Iron, and Aluminum

As an illustration, this video shows how effortless removing gates and risers from castings and cutting through plate steel can be. A robot, paired with a PushCorp force compliance device and servo spindle, is just what you need to automate your material-removal process.

This video showcases our STC0612-BT40. The STC0612-BT40 is a 12 horse power spindle with a max RPM of 6,000. Its powerful motor provides a constant RPM and high torque to power through these cutoff applications.

Abrasive cutoffs work at an extremely fast rate. These clips utilize bonded cutoff wheels and diamond coated saws. Your cutoff method will depend on metal type, its thickness, and set precision requirements.

We recommend:

Application Engineers With the Experience to Help You Succeed

Our application engineers have years of experience and can help recommend the right process equipment for your project. If you are new to integration or this is your first material-removal application, we are here to help. For more robotic, material-removal videos, make sure to check out our content below.

PushCorp Robotic Gate Removal

PushCorp Robotic Gate Removal

What Are You Waiting For? Get in Touch With Our Application Engineers Today! With 1000’s of systems sold, we have the equipment needed to make your project a success. Our application engineers are ready to learn about your process and help recommend the right products for your robotic surface finishing system.

With 1000’s of systems sold, we have the equipment needed to make your project a success. Our application engineers are ready to learn about your process and help recommend the right products for your robotic surface finishing system.