Automate Material

Removal with

Robotic Precision

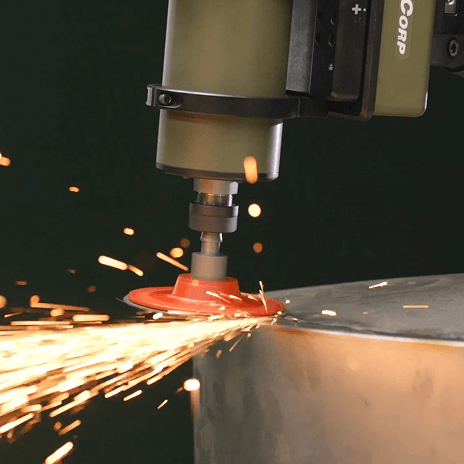

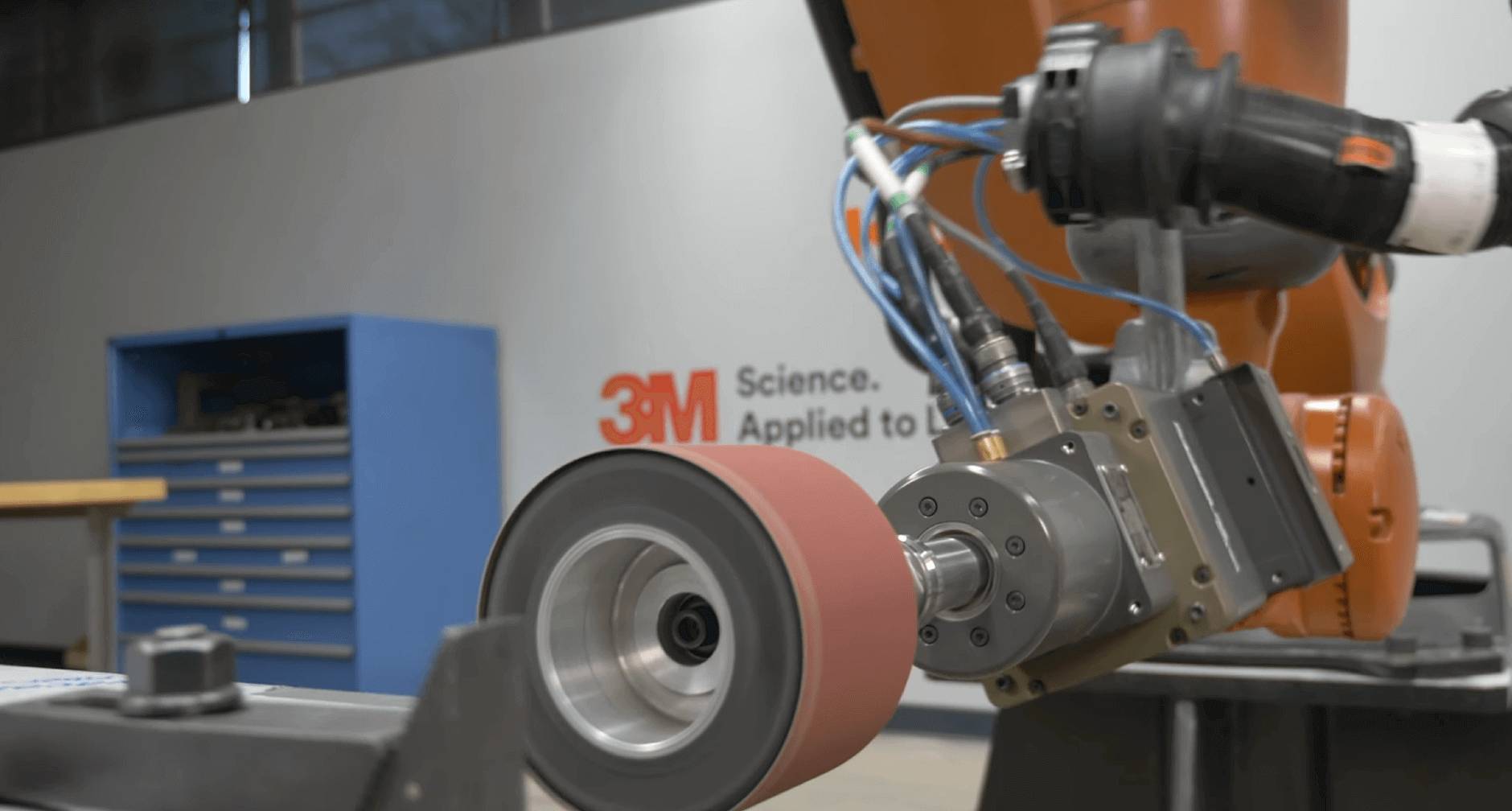

PushCorp specializes in robotic tooling solutions that make it easier for manufacturers to automate tough, repetitive, and often dangerous material removal tasks.

From grinding and sanding to weld shaving and gate removal, our application-focused tooling is backed by over 30 years of innovation, bringing safety, consistency, and efficiency to your production floor.

Whether you are a small shop taking your first steps into robotics or a large manufacturer looking to scale throughput, our material removal robot tooling

solutions are built to simplify automation and achieve high quality results faster