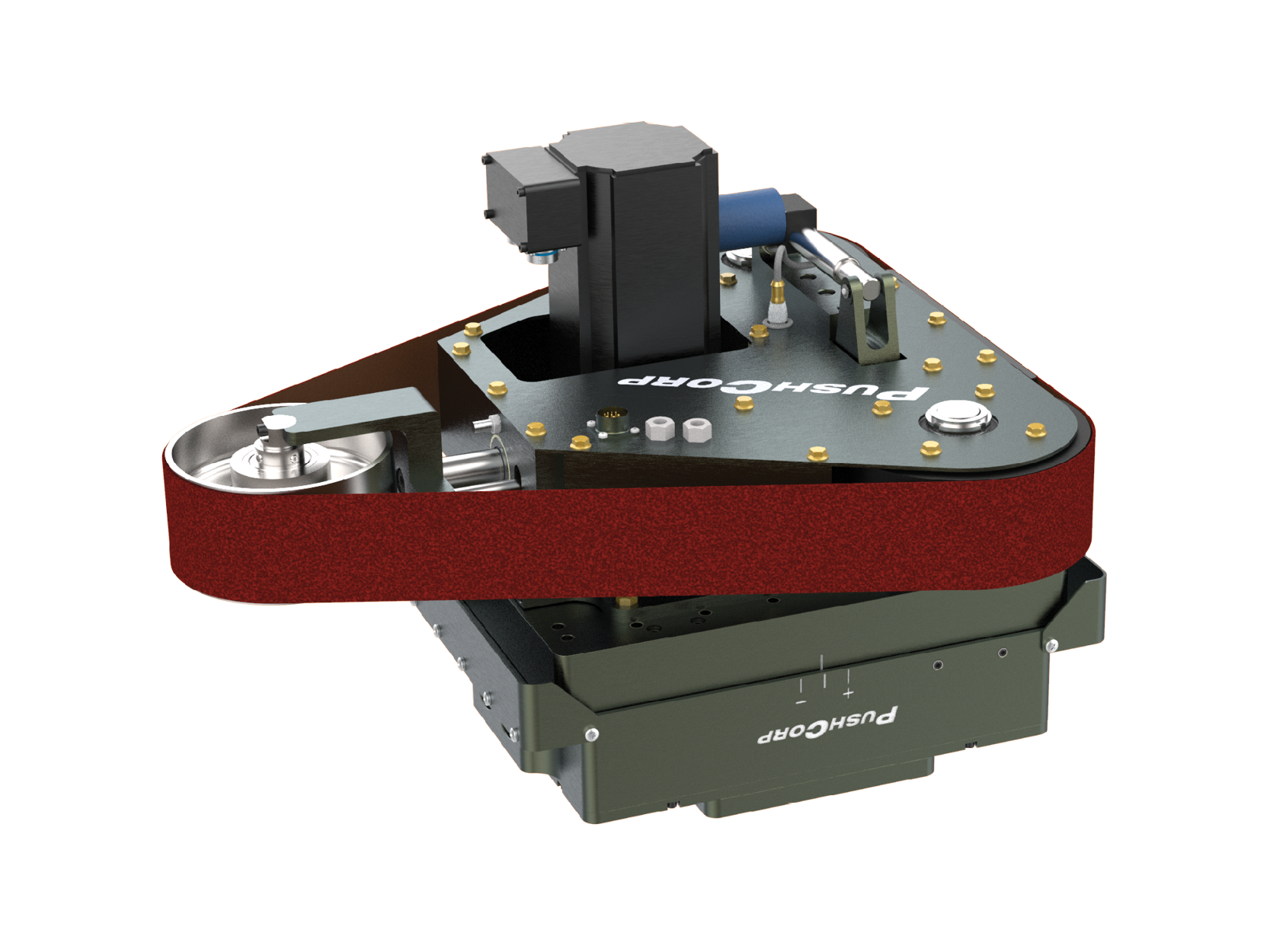

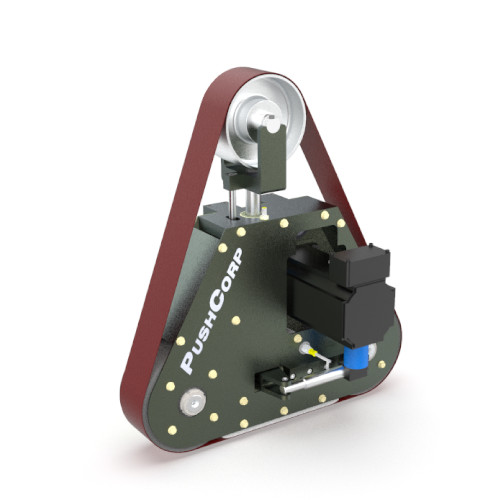

Automate the Toughest Grinding Jobs with PushCorp GrindX

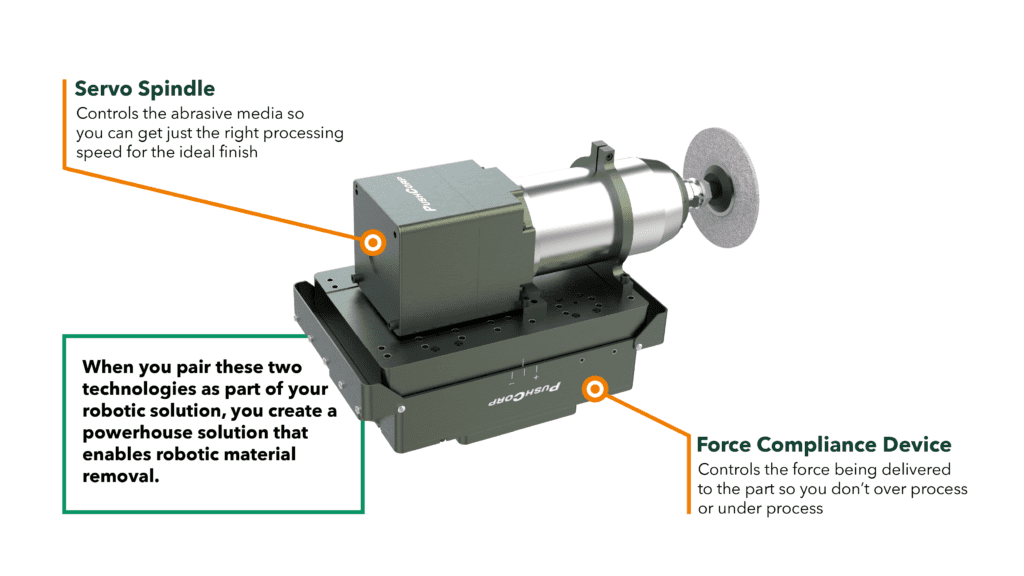

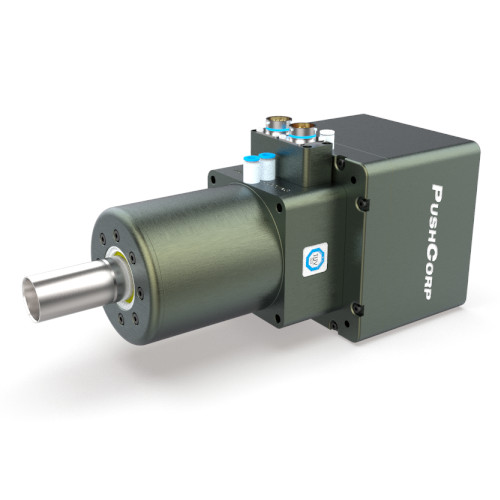

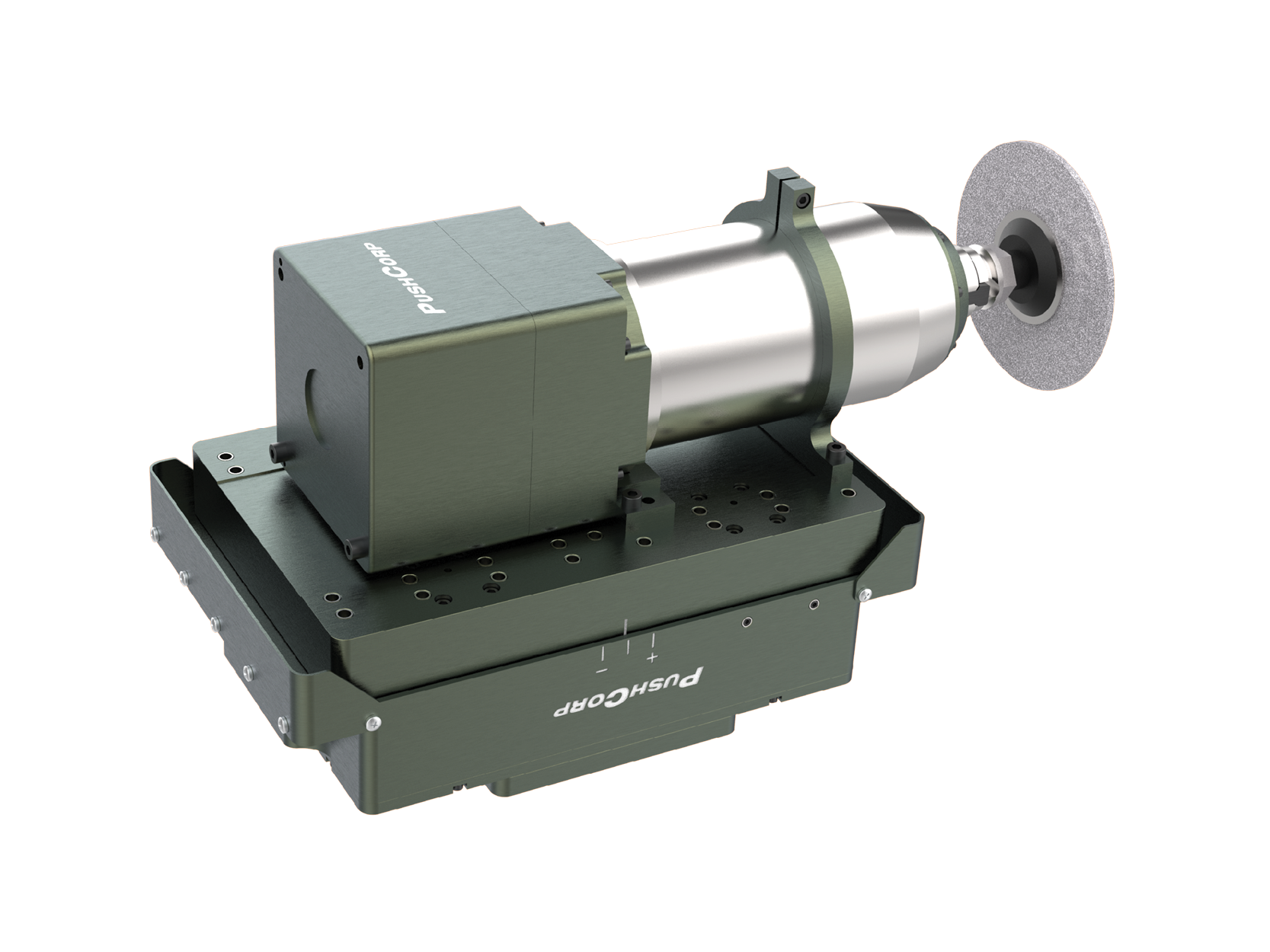

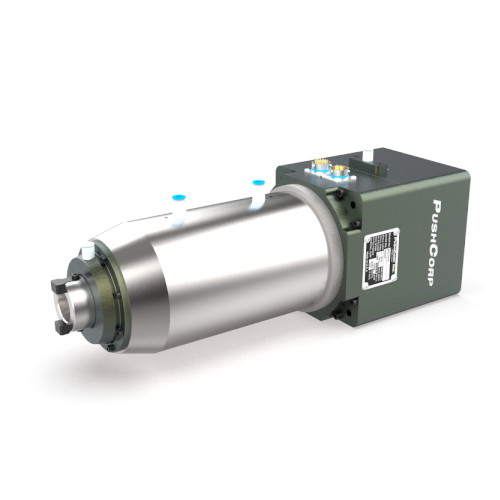

From smoothing weld seams to beveling edges, PushCorp GrindX™ is built to tackle the toughest grinding applications with ease. Manual grinding is not only physically demanding but also prone to inconsistencies that lead to rework. PushCorp GrindX eliminates these challenges by automating weld removal, delivering uniform edge preparation, and handling heavy material removal with precision. By integrating PushCorp GrindX into your production line, you can improve efficiency, reduce strain on your workforce, and achieve consistent, high-quality finishes every time.