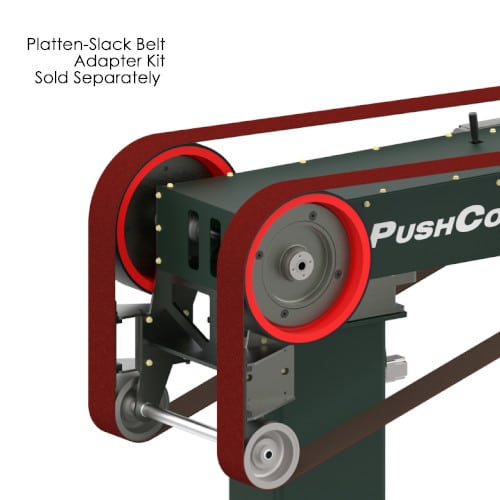

SBS81 Series

Servo Belt Stand

The PushCorp SBS81 Servo Belt Stand combines compliant force control with a high-torque 5.7 hp [4.28 kW] servo motor. This precise force and speed control allows you to achieve unprecedented levels of quality and consistency.

The SBS81 Servo Belt Stand is designed to enable maximum flexibility for any robotic part-in-hand material removal application. Linear travel compliance and excellent access allow a robot to easily manipulate parts over the belt media and perform the following operations.

- Grinding (casting gates, weld beads)

- Deburring (parting lines, chamfer)

- Polishing (glass, wood, metal)

If the application will have impact loading, interrupted cuts, or require more torque, the SBS91 is the largest Belt Stand in the series. It features a robust set of linear bearings, can apply 250 lbf [1112 N], and has 62 lb· ft [84 N·m] continuous stall torque.

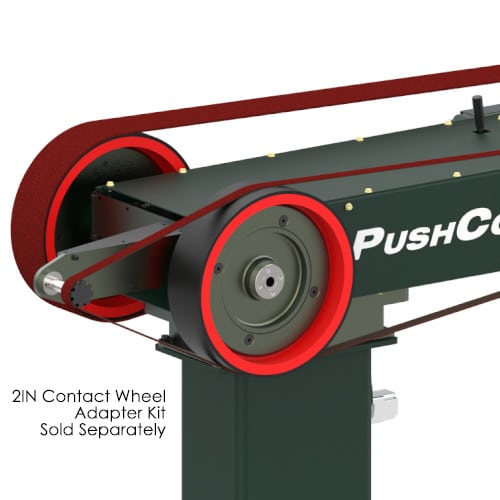

The contact wheels of the SBS81 Servo Belt Stand are belt driven by a high-torque servo motor. This drive system has a 2:1 reduction that provides plenty of power at the contact wheels. The belt media is tracked remotely keeping personnel out of the workcell during operation. Easily removable contact wheels allow widths of 1", 2", 3", and 4", plus a wide range of different rubber hardness. Changing the belt media is a snap with pneumatic tension and conveniently positioned manual valves.