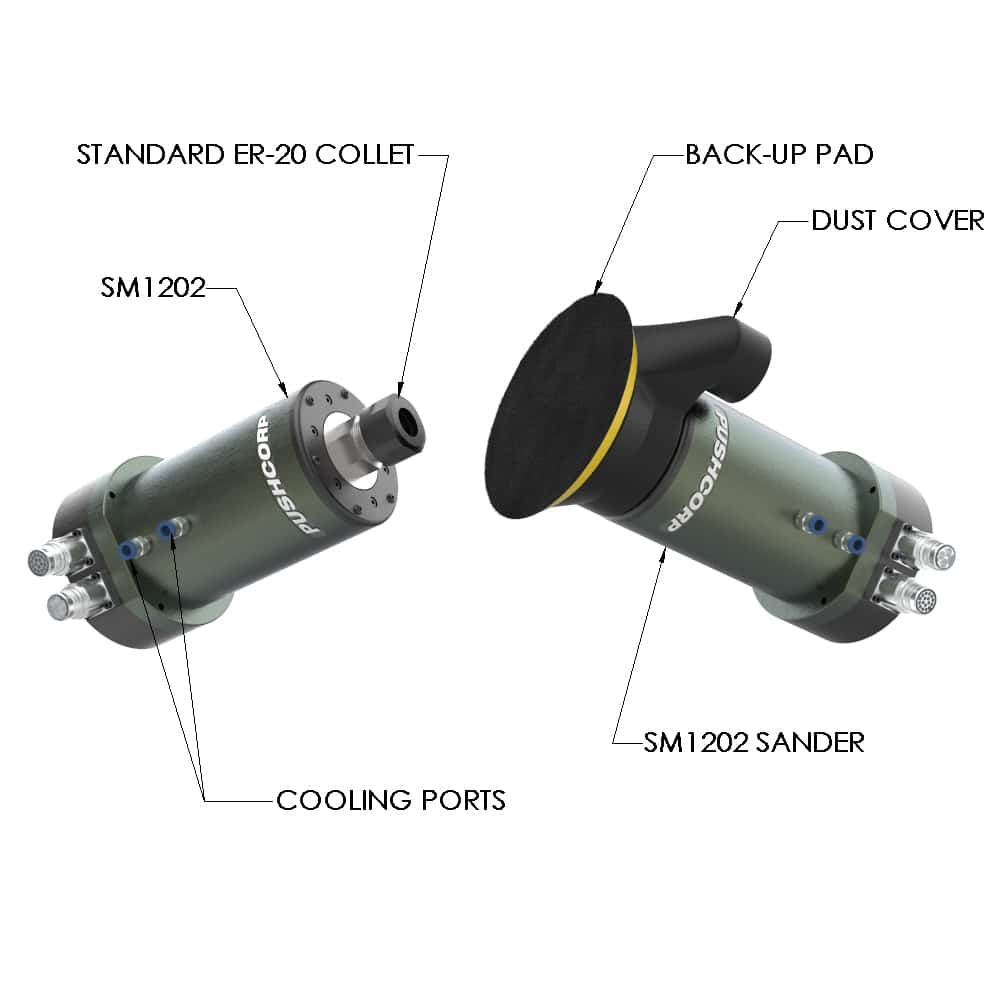

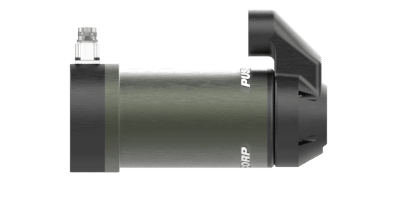

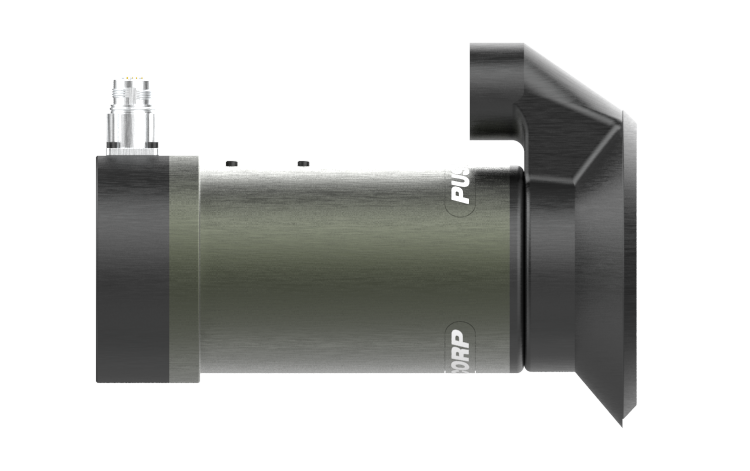

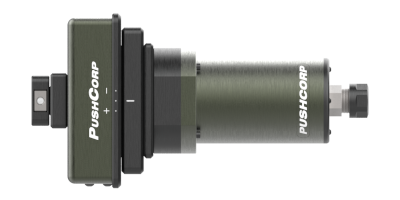

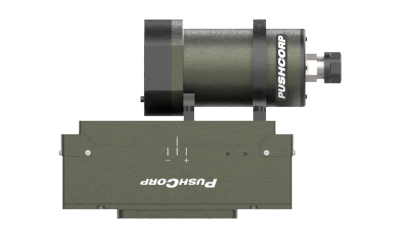

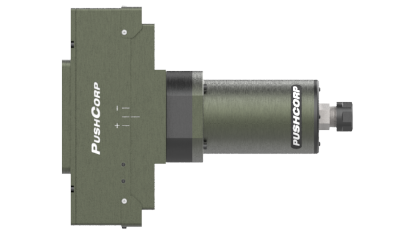

SM1202

The “ER” Series features an ER20 collet, which is used to clamp the tool shaft. This means that operator intervention is required when the media needs to be replaced. For applications where the abrasive media or the tools have a long life, the manual collet is the ideal solution.

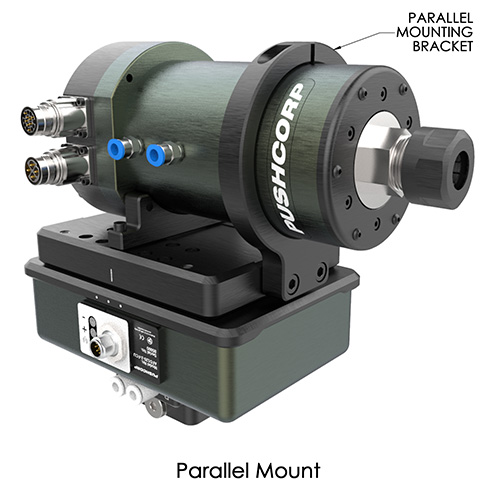

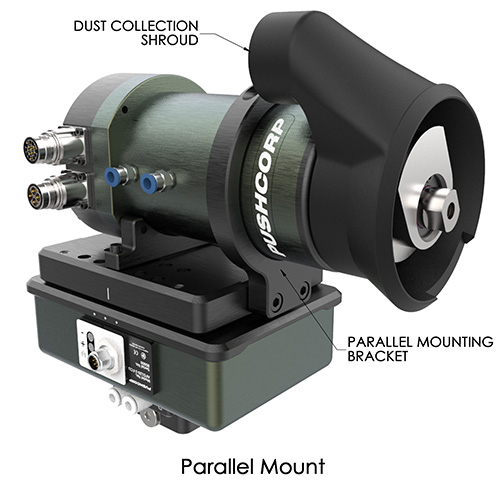

The SM1202 has been developed as a lighter, more compact alternative to the SM1503. It features a powerful 2.0 hp [1.49 kW] servo motor that provides constant speed. This equipment is designed to mount in a parallel or perpendicular orientation on the AFD310 and AFD72 force compliance devices. As a result, it has never been easier to program beautiful and consistent surface finishes.

Features

- 2.0 horsepower [1.49kW] servomotor

- 12,000 maximum RPM

- Fully adjustable and reversible speed

- Manual “ER” Series collet

- Collets available from 1/16 – 1/2 inch [1 – 12mm]

- Sealed bearings for long service life

- PushCorp high-speed shaft seal

- Mounts directly to PushCorp Active and Passive compliant tools

- All fittings, fasteners, and threaded holes are METRIC

SPECIFICATIONS

| Model | SM1202 |

| Power | 2.0 hp [1.49 kW] |

| Continuous Stall Torque | Air Cooled - .74 lb.-ft. [1.0 N·m] Liquid Cooling - 1.33 lb.-ft. [1.8 N·m] |

| Speed Range | 0-12,000 RPM |

| Speed Regulation | ±5% (Reversible) |

| Cooling | Air or Liquid (Duty Cycle Dependant) |

| Tool Weight | 9 lb. [4.1 kg] Dry |

| Required Toolholder | Standard ER-20 Collet |

| Technical Specification Packages | ||

|---|---|---|

|

SM1202 | Download Technical Files |

|

SM1202 SANDER 3IN | Download Technical Files |

|

SM1202 SANDER 5IN | Download Technical Files |

|

SM1202 SANDER 6IN | Download Technical Files |

|

SM1202 SANDER 3IN-AFD120-2-Parallel | Download Technical Files |

|

SM1202 SANDER 3IN-AFD310-2-Parallel | Download Technical Files |

|

SM1202 SANDER 5IN-AFD120-2-Parallel | Download Technical Files |

|

SM1202 SANDER 5IN-AFD310-2-Parallel | Download Technical Files |

|

SM1202 SANDER 6IN-AFD120-2-Parallel | Download Technical Files |

|

SM1202 SANDER 6IN-AFD310-2-Parallel | Download Technical Files |

|

SM1202-AFD62-1-Parallel | Download Technical Files |

|

SM1202-AFD62-1-Perpendicular | Download Technical Files |

|

SM1202-AFD62-2-Parallel | Download Technical Files |

|

SM1202-AFD62-2-Perpendicular | Download Technical Files |

|

SM1202-AFD310-2-Parallel | Download Technical Files |

|

SM1202-AFD310-2-Perpendicular | Download Technical Files |

|

SM1202-RPS100-3IN-AFD62-2-Parallel | Download Technical Files |

|

SM1202-RPS100-5IN-AFD62-2-Parallel | Download Technical Files |

|

SM1202-RPS100-6IN-AFD62-2-Parallel | Download Technical Files |